Pad peeling off, also call pad pad shadding, refers to the phenomenon that the pad is separated from the PCB. This is a common adverse phenomenon in the PCBA processing , especially in the subsequent maintenance process. The pad refers to the conductive pattern that provides electrical connection on the PCB. As a necessary medium for the soldering and assembly of electronic components and PCB circuit boards, the importance of the pad is self-evident. Once the pad peels off, it will lead to PCBA products cannot be used normally.

As a PCB circuit board manufacturer, we must be able to analyze the reasons and solve problems for customers. Next, AiXun Smart Precision Soldering will conduct some analysis on the reasons for the pads shedding, and take effective measures for the reasons.

There are several common causes of PCB pad shedding

1. PCB circuit board quality problems

Since the resin adhesive between the copper foil of the copper clad laminate and the epoxy resin is relatively poor, even if it is a circuit board with a large area of copper foil, the copper foil is very easy to bond with the epoxy resin when it is slightly heated or under mechanical external force. Resin separation causes problems such as pad peeling off or copper foil detachment.

2. The influence of circuit board storage conditions

Affected by the weather or due to long-term storage in a humid place, the circuit board absorbs moisture and contains too much moisture. In order to achieve the ideal soldering effect, the heat taken away by moisture volatilization must be compensated during patch soldering, and the soldering temperature and time must be extended. Such soldering conditions are likely to cause delamination of the copper foil and epoxy resin on the circuit board. Therefore, PCB factories should pay attention to the humidity of the environment when storing circuit boards.

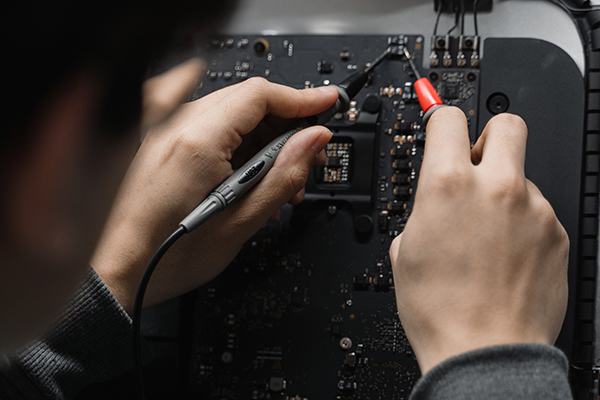

3. Problem of electric soldering iron

Generally, the adhesion of circuit boards can meet the requirements of ordinary soldering, and there will be no phenomenon of pad falling off. However, electronic products are generally likely to be repaired. The repair is usually done by soldering with an electric soldering iron. Because the local high temperature of the electric soldering iron often reaches 300-400 ° C, As a result, the local instantaneous temperature of the pad is too high, and the resin under the soldered copper foil falls off due to high temperature, and the pad falls off. When the soldering iron is disassembled, it is easy to attach the physical force of the soldering iron tip to the pad, which is also the reason for the pad to fall off.

In view of the fact that the pads are easy to fall off under the conditions of use, the circuit board factory adopts the following aspects to increase the soldering resistance of the pads of the circuit board as much as possible to meet the needs of customers.

1: Copper-clad laminates are made of substrates produced by quality-assured manufacturers. Generally, the glass fiber cloth material selection and pressing process of genuine copper clad laminates can ensure that the solder resistance of the manufactured circuit boards meets the customer's requirements.

2: Aiming at the thermal shock to the soldering pad when the soldering iron is reworked, we try to increase the thickness of the copper foil of the soldering pad by electroplating. In this way, when the soldering iron heats the soldering pad, the thermal conductivity of the copper foil pad is significantly enhanced, effectively Reduce the local high temperature of the pad. At the same time, the fast heat conduction makes the pad easier to disassemble, achieving the solder resistance of the pad.

3: The circuit board is vacuum-packed before leaving the factory, and a desiccant is placed to keep the circuit board in a dry state. Create conditions for reducing virtual soldering and improving solderability.

After understanding these problems, you can clearly analyze the reasons and help customers solve the problems better. Shenzhen Aixun Intelligent Hardware Co., Ltd. is a high-tech enterprise dedicated to providing intelligent solutions in the field of precision electronic soldering. For more questions about circuit board soldering processing or industry information, please contact AiXun official website.

WhatsApp

WhatsApp