With each passing year, tablets, phones and almost every other electrical device manufactured is getting smaller. This means that smaller and smaller electrical components have to be fitted into the casing of these thinner and thinner devices. This is where precision soldering station come in!

For manufacturers dealing with such devices, greater accuracy is paramount when soldering miniature components onto the smaller PCB.

Fortunately, AiXun offers the ideal solutions for all your precision soldering needs.

Precision soldering can be challenging for several reasons:

Small components: Precision soldering often involves working with tiny components, such as surface-mount devices (SMD) or delicate wires. The small size can make it difficult to manipulate the components and position them accurately for soldering.

Heat control: Soldering requires the application of heat to melt the solder and create a reliable connection. However, excessive heat can damage sensitive components or surrounding materials. Achieving the right temperature without overheating the area requires careful control and technique.

Limited workspace: Precision soldering often occurs in confined spaces, such as circuit boards or intricate electronic devices. This limited workspace can make it challenging to access the soldering area and maneuver the soldering iron and solder.

Fragile connections: In precision soldering, the connections being made are typically delicate and require precise alignment. Any misalignment or excess solder can result in poor electrical conductivity or even damage the components.

Solder flow control: Ensuring proper solder flow is crucial for achieving reliable connections. It can be difficult to control the flow of solder in small spaces, and excess solder or solder bridges can cause short circuits or unreliable connections.

Visual clarity: Precision soldering often requires a high level of visual clarity to ensure accurate placement and soldering. The small size of components and intricate soldering points can make it challenging to see fine details, leading to errors or imperfect solder joints.

Skill and experience: Precision soldering requires skill and experience to perform consistently well. It takes time to develop the necessary hand-eye coordination, steady hand, and technique to achieve precise soldering results.

Overcoming these challenges requires practice, patience, and attention to detail. With experience and the right tools, precision soldering can become more manageable and yield high-quality results.

There are several ways to do precision soldering, but here are a few key techniques that can help ensure a successful soldering job:

1. Use a high-quality soldering iron with a small tip. This will allow you to focus heat more precisely on the area you want to solder.

2. Use a microscope or magnifying glass to get a better view of the area you are soldering. This will help you see any defects or areas that need extra attention.

3. Use a steady hand and a steady pace. This will help you avoid mistakes and keep the soldered area neat and tidy.

4. Use flux to help the solder flow more easily. This will help you achieve a cleaner, more precise solder joint.

5. Use a desoldering tool to remove any excess solder. This will help you achieve a clean, precise solder joint.

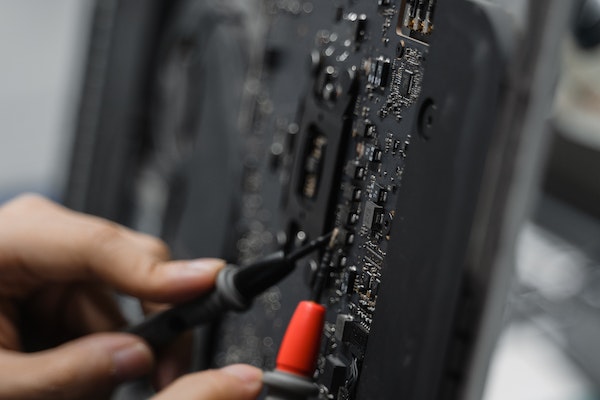

6. Use a multimeter to test the continuity of the soldered joint. This will help you ensure that the connection is strong and reliable.

Practice, practice, practice! The more you do it, the better you'll become at precision soldering.

It's also important to note that safety must be a priority when soldering. Always wear safety glasses and make sure to work in a well-ventilated area.

Here are some tools and equipment that can aid in precision soldering:

Fine-tipped soldering iron: A soldering iron with a small and fine tip allows for precise application of heat to specific areas. Look for a temperature-controlled soldering iron that offers adjustable heat settings.

Magnifying glass or microscope: These tools help magnify the work area, enabling better visibility of small components and soldering points. They assist in achieving greater accuracy and reducing the risk of errors.

Helping Hands: These tools consist of adjustable clips or arms that hold the workpiece in place, leaving your hands free to focus on soldering. They are particularly useful when working with small or delicate components.

Soldering tweezers: Tweezers with fine tips are handy for holding small components in position during soldering. They provide better control and precision when placing components onto the soldering area.

Flux pen or flux dispenser: Flux is used to improve solder flow and remove oxidation from surfaces. A flux pen or dispenser allows you to apply a small amount of flux precisely where it's needed.

Soldering station with temperature control: A soldering station with adjustable temperature control ensures that you can set the appropriate heat level for the specific soldering task. Maintaining consistent temperature is crucial for precision soldering.

Desoldering tools: These tools help remove excess solder or correct soldering mistakes. Desoldering wick or a desoldering pump can assist in removing solder from joints cleanly and precisely.

Fine-gauge solder: Using thin solder, such as 0.025-inch or 0.020-inch diameter, is beneficial for precision soldering. It allows for better control and reduces the risk of applying too much solder.

Anti-static wrist strap: When working with sensitive electronic components, an anti-static wrist strap can help prevent static discharge that may damage the components.

Ventilation system: It's important to work in a well-ventilated area or use a fume extractor to remove soldering fumes and ensure a safe working environment.

Remember to choose high-quality tools that suit your specific soldering needs. Investing in reliable equipment can greatly enhance your precision soldering capabilities.

AiXun have developed ranges of innovative precision soldering stations. And newly released the T320 Integrated Precision Smart Soldering Station! It is excellent option for any kind of rework or soldering works with miniature components on a PCB.

WhatsApp

WhatsApp