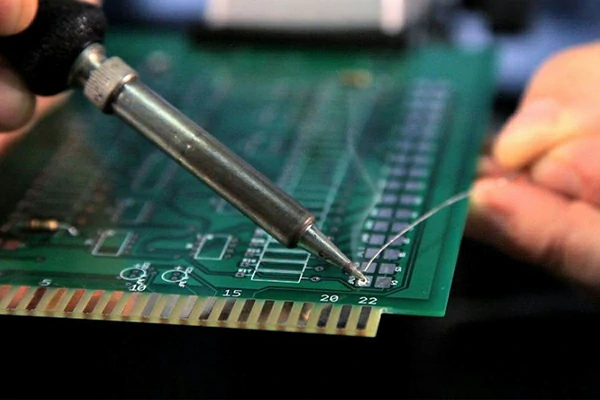

Any electronic product, from a few parts constitute the rectifier to thousands of parts of the computer system, are composed of basic electronic component devices and functions, according to the principle of circuit operation, with a certain process method of connection and become. Although there are a variety of connection methods (for example, winding, crimping, bonding, etc.), but the most widely used method is soldering. In the electronics industry, hand soldering is the simplest and most common method of soldering.

· soldering iron/soldering station

· chrome iron stand

In order to improve the quality of soldering, attention must be paid to mastering the conditions of tin soldering

· The soldered parts must be solderable.

· The metal surface to be soldered should be kept clean

· Use the appropriate flux

· with the appropriate soldering temperature

· with the appropriate soldering time

Any metal or alloy that is used to fuse two or more metal surfaces into a single unit is called solder. The solder mentioned here is only for the solder used in tin soldering.

· Tubular Solder Wires

· antioxidant solder

· Silver-containing solder

· solder paste

In the soldering process, due to the metal in the case of heating will produce a thin layer of oxide film, which will hinder the infiltration of solder, affecting the formation of welded alloy, prone to false welding, false welding phenomenon.

The use of flux can improve soldering performance. Flux rosin, rosin solution, solder paste and soldering oil, etc., according to different welding objects can be reasonably selected. Soldering paste and soldering oil and other corrosive, can not be used for welding electronic components and circuit boards, welding should be soldered at the end of the residual soldering paste and soldering oil and other wiping clean. Component pins should be tinned with rosin as flux. Printed circuit boards have been coated with rosin solution, components welded in without having to use flux.

Hand soldering technique is a basic skill, that is, in mass production, maintenance and repair must also use hand soldering. Therefore, it must be learned and practiced through hands-on practice to master it. Precautions are as follows: the correct operating posture of the hand-chromium iron hand-chromium iron posture mastery of the correct operating posture, can ensure the physical and mental health of the operator, to reduce labor injuries. In order to reduce the flux heating volatile chemical substances on the harm, reduce the amount of harmful gas inhalation, in general, the soldering iron to the nose distance should be not less than 20cm, usually 30cm is appropriate.

WhatsApp

WhatsApp