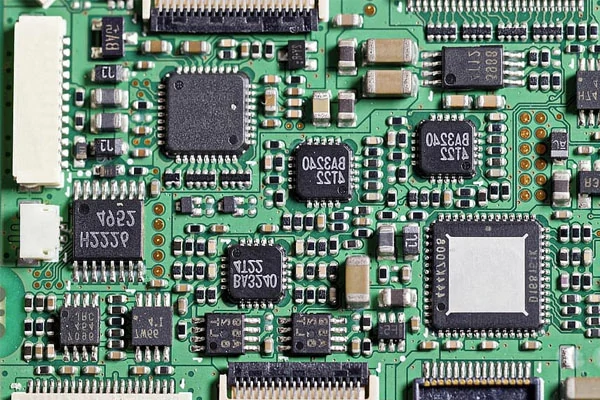

In the world of electronics where things keep getting smaller and smarter, Surface Mount Devices (SMD) play a vital role. They power our gadgets and devices with their compact efficiency. However, working with these tiny components can be a challenge. That's where a reliable soldering station for SMD work comes into play.

In this article, we'll explore the world of soldering station designed specifically for SMD projects We'll explain why having the right soldering station is crucial for anyone involved in electronics, whether you're a seasoned pro or just starting out.

So, if you're ready to dive into the world of precise soldering, keep reading. We'll break down the essential aspects of soldering stations for SMD, helping you make informed decisions for your electronic projects. Whether you're soldering microcontroller, LED, or other SMD components, having the right soldering station can make your work more efficient and enjoyable. Let's get started!

When it comes to soldering stations for Surface Mount Device (SMD) work, there are various types to choose from. Each type offers distinct advantages depending on your specific needs and preferences.

Temperature-Controlled Soldering Station: These stations allow precise temperature adjustment, which is crucial for SMD soldering. They often come with digital displays for accurate temperature monitoring.

Hot Air Soldering Station: Ideal for SMD rework and desoldering, hot air stations use a stream of hot air to melt solder. They are excellent for removing and replacing SMD components without damaging nearby parts.

Soldering Irons with Fine Tips: These are specialized soldering irons with fine, pointed tips designed for delicate SMD work. They are an excellent choice for intricate soldering tasks.

Selecting the right soldering station for SMD work requires careful consideration of its features. Here are some essential features to keep in mind:

Adjustable Temperature: Look for stations with adjustable temperature settings. SMD components often require precise temperature control, and the ability to fine-tune the heat is crucial.

Quick Heat-Up Time: A soldering station with a fast heat-up time gets you working more quickly, saving valuable time during your projects.

Temperature Stability: Temperature stability ensures that the soldering station maintains the selected temperature consistently, preventing overheating or underheating during use.

Investing in a soldering station designed for SMD work offers several benefits:

Precision: SMD components are tiny, and precision is key. Soldering stations provide the control you need for accurate soldering.

Efficiency: With the right tools and temperature settings, you can complete SMD soldering tasks more efficiently.

Considerations When Choosing a Soldering Station

When you're in the market for a soldering station for SMD work, here are some factors to consider:

Budget: Determine your budget and find a soldering station that meets your needs without breaking the bank.

Brand and Reputation: Research reputable brands known for quality soldering stations. Read reviews and gather recommendations from experts or fellow hobbyists.

Accessories: Check if the soldering station comes with essential accessories like fine soldering tips, stands, and cleaning tools.

Warranty and Support: Ensure that the soldering station comes with a warranty and reliable customer support in case you encounter any issues.

Here are some practical tips to enhance your SMD soldering experience:

Practice: SMD soldering can be challenging, so practice on scrap components before working on your actual projects.

Use Flux: Apply flux to components before soldering. It improves solder flow and helps create clean, reliable joints.

Clean Your Iron: Keep your soldering iron tip clean by regularly wiping it with a damp sponge or using a specialized tip cleaner.

SMD soldering stations find applications in various fields, including:

Electronics Repair: Repairing smartphones, laptops, and other gadgets often involves SMD soldering.

Prototyping: Creating prototypes for innovative electronic devices often requires precise SMD soldering techniques.

Selecting the right soldering station for SMD work involves understanding the types, features, and benefits they offer, considering various factors, and following practical tips. By making an informed choice, you can enhance your SMD soldering capabilities and tackle a wide range of electronic projects with confidence.

AiXun-The Intelligent & Precision Soldering Expert, provide pro-solutions in soldering field. Want to become a dealer or distributor, feel free to contact.

WhatsApp

WhatsApp