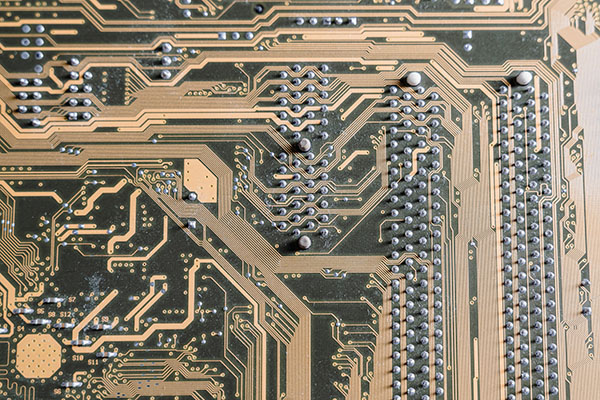

PCB is the basic component of electronic products. For products with different uses, the PCB that need to be selected are also different. Usually we use the number of layers, substrate material, and scope of application to classify PCB. Today, AiXun Precision Soldering Tool will share with you the classification of PCB.

1. According to the number of PCB board layers, it is generally divided into: single-sided board, double-sided board and multi-layer board.

The single-sided board is to concentrate all the components on one side of the PCB board, so it is called a single-sided board. Because the area of a single-sided board is limited, the circuit design will be relatively simple, and it is only suitable for electronic products with simple functions.

Double-sided board means that there are components and circuits on both sides of the PCB board. Under the same size, the designable area will be double that of the single-panel panel, which can effectively solve the electromagnetic interference problem caused by the interlacing of wires in the single-panel panel. It can also reduce the volume of the product, and can be used in products with complex circuit designs.

The multi-layer board is composed of single-layer and double-layer boards. The most common is to use two double-layer boards as the inner board, and then use two single-layer boards on the outside, and combine the positioning system with insulating and adhesive materials to form a four-layer board. Of course, the number of layers can be increased according to the design of the product, usually an even number of layers. The design of the multi-layer board improves the area and density of the wiring, and can do more complex circuit design. The components of the multi-layer board are more patch-type components, the layout of the components is more precise, so the product can be made lighter , more compact and small.

2. According to the nature of PCB substrates, it can generally be divided into: rigid circuit board, flexible circuit board, and rigid-flex printed circuit board.

The main materials of rigid circuit board is made of FR-4, CEM-1, CEM-3, metal-based copper-clad laminates (mainly aluminum-based, and a few iron-based).

FR-4 is a glass fiber board laminated with copper foil and impregnated flame retardant epoxy resin fiber cloth, which has good machinability.

CEM-1 is a composite substrate made of glass fiber on the upper and lower surfaces, and a paper material impregnated with phenolic resin in the middle. The mechanical processability and electrical performance are not as strong as FR-4, but the price is cheap.

CEM-3 is a composite glass fiber board. Its glass transition temperature, dip soldering resistance, peel strength, water absorption, electrical breakdown, insulation resistance, and UL indicators have all reached the level of FR-4. But the flexural strength is lower than FR-4.

Metal-based copper-clad laminates are generally composed of three parts: a metal substrate, an insulating dielectric layer and a conductive layer (usually copper foil), which are hot-pressed and composited. The biggest feature of metal-based copper-clad laminates is excellent heat dissipation performance and dimensional stability.

Generally, rigid circuit boards are used in electronic products. Rigid circuit boards have certain mechanical strength, and the resulting PCB has flatness and can maintain a good overall state.

Flexible circuit boards are mostly made of soft layered plastics such as polyester film, polyimide film, and fluorinated ethylene propylene film. The flexible circuit boards made can be bent and stretched, which is convenient for special installation according to installation requirements during use. .

Rigid-flex board is a combination of rigid circuit board and flexible circuit board related process requirements to form a circuit board with FPC characteristics and PCB characteristics. It can be used in some products with special requirements.

3. According to the scope of application, PCB can be divided into high frequency and low frequency.

High-frequency electronic products are the current development trend. PCB high-frequency boards have been widely used in the current communication industry, network technology and high-speed information processing systems. Because the dielectric constant of high-frequency boards is small, so the heating efficiency and signal transmission speed of the high-frequency board are very fast. At the same time, because the material of the high-frequency board has low water absorption, it can be applied to a more humid environment. The application range is much larger than that of the low frequency board.

In the past ten years, PCB circuit boards have been increasingly used in almost every kind of electronic equipment, from small electronic watches and calculators to large computers, communication electronic equipment, and military weapon systems. As long as there are electronic component systems with integrated circuits , In order to make the electrical interconnection between the various components, a PCB board is used. Manual soldering tools for PCB boards, we usually use electric soldering iron or electric soldering station. Want to know the difference between soldering station and soldering iron: Soldering Station VS Soldering Iron: Which Is Better?

Follow AiXun, we update daily!

WhatsApp

WhatsApp