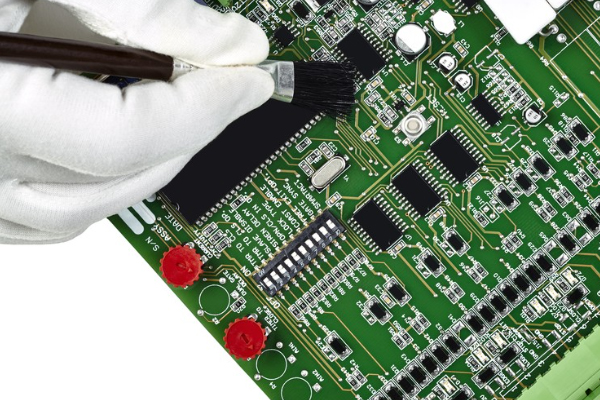

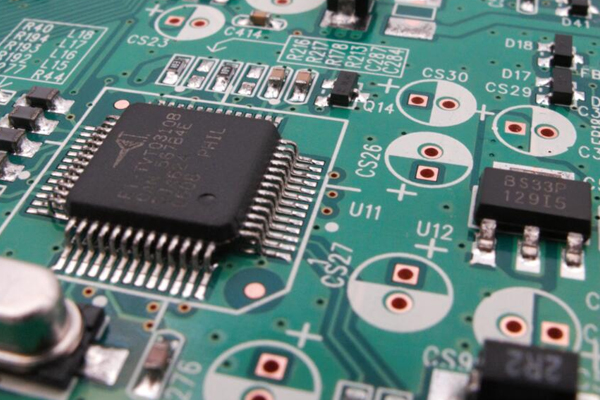

After the BGA is removed,the residue of PCB pads should be cleaned, mainly to remove the flux and residue left on the PCB surface after the chip is removed. We can use cleaning agents that meet the requirements. At the same time, in order to ensure the smooth progress of the BGA soldering, the solder paste remaining on the pad should be removed with a tin suction tape to ensure the flatness of the PCB surface to ensure the flatness of the PCB surface and then the disassembled BGA should be cleaned of the solder residue for use in BGA ball implantation.Due to the small size of BGA chips, it is more difficult to clean the pads, so when reworking small size chips, if the space around is small, you need to use cleaning flux.

Applying solder paste to the PCB has a significant impact on the BGA rework results. By selecting a template that matches the chip, the solder paste can be easily applied to the pads. When applying the solder paste, attention should be paid to the uniformity of the solder paste at each point. In general, BGA solder balls cannot be completely removed from the PCB, half of the BGA solder balls remain on the assembly and the other half on the component, usually like a solder post, so the entire ball needs to be rearranged prior to any rework attempt. Use the soldering iron to clean up the residual solder of the PCB pad and make it smooth, you can use the desoldering braid and flat spatula-shaped soldering iron tip to clean up, take care not to damage the pad and solder resist film, use the special cleaning agent to clean the flux residue.

First aid for welding burns:

Most welding burns can be mild and treatment is simple:

Immediately cool affected area with mild cold water.

Place the burned area in cold water for at least 5 minutes (15 minutes recommended). This may also help if ice is readily available, but do not delay the initial cooling with cold water.

Do not apply any cream or ointment.

Burns heal better without them. If you want to protect the area from dirt, you can use a dry dressing, such as a clean handkerchief.

If the burn is larger than your hand, please seek medical attention.

To reduce the risk of burns:

Be sure to put the soldering iron back on its holder immediately after use.

Let the joints and components cool for a minute or so before touching them.

Never touch the components or tip of the soldering iron unless you are sure it is cold.

The above are the emergency measures provided by aixun on how to clean the residue after the BGA is removed and the burns caused by insufficient operation. As long as it is welding, there will be risks, so we must pay attention to safety during the welding process, standardize the welding operation, and ensure the quality of use. soldering station. It will reduce all kinds of accidents during welding. If you have any questions about welding, please consult us and we will help you.

WhatsApp

WhatsApp