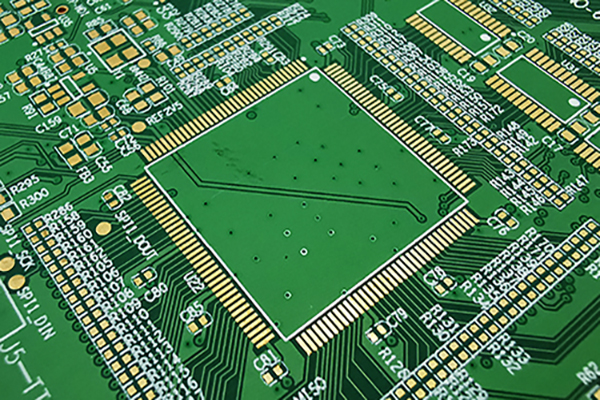

While testing tools provide a more accurate and comprehensive assessment of PCB (Printed Circuit Board) quality, there are several visual and manual checks you can perform without specialized equipment. Here are some methods to judge the quality of a PCB board without testing tools:

1. Visual Inspection:

Solder Joints: Examine solder joints for consistency and smoothness. Good solder joints should be shiny and evenly distributed.

Component Placement: Check if components are correctly placed and aligned. Misaligned or skewed components may indicate poor manufacturing quality.

Traces and Pads: Inspect the copper traces and pads for any signs of damage, discoloration, or poor adhesion.

2. Component Quality:

Component Brands: Reputable brands are more likely to produce high-quality components. Check the markings on integrated circuits and other components to identify their origin.

Visual Inspection of Components: Look for any physical damage, discoloration, or irregularities on the components.

3. Board Surface:

Surface Finish: A quality PCB should have a smooth and even surface finish. Check for any roughness or irregularities in the board surface.

Solder Mask: Ensure that the solder mask is evenly applied and free from scratches or gaps. It helps prevent solder bridges and ensures insulation between conductive traces.

4. Alignment and Symmetry:

Component Alignment: Check that components are symmetrically placed and aligned. Lack of symmetry may indicate errors in the manufacturing process.

Alignment of Layers: If it's a multilayer PCB, inspect the alignment of different layers. Misalignment may lead to electrical issues.

5. Quality of Silkscreen Printing:

Text and Markings: Silkscreen printing should be clear, with easily readable text and markings. Faded or unclear printing may suggest a lower-quality PCB.

6. Weight and Thickness:

Weight: High-quality PCBs are generally denser. Compare the weight of the PCB to similar boards if possible.

Thickness: Measure the thickness of the PCB with a caliper. A consistent thickness across the board is an indicator of good manufacturing.

7. Documentation and Certifications:

Documentation: A reliable PCB manufacturer provides comprehensive documentation, including datasheets and specifications.

Certifications: Check if the manufacturer adheres to industry standards and holds certifications such as ISO 9001.

8. Functionality Testing:

Manual Checks: If possible, perform manual functional checks to ensure that the board performs as intended. This may not replace specialized testing but can identify obvious issues.

While these methods offer a basic assessment, it's important to note that some defects or issues may not be visible without proper testing equipment. If the PCB is critical for a project, it's recommended to use professional testing tools or consult with a quality assurance expert.

>> Click to view the history of PCB

WhatsApp

WhatsApp