Congratulations on owning a hot air rework station! This powerful tool is your trusted companion for intricate soldering and rework tasks. To ensure its longevity and reliable performance, proper maintenance is key. In this article, we will guide you through a series of steps to actively maintain your hot air rework station. By following these practices, you'll enjoy a smoothly operating tool that delivers precision and efficiency for years to come.

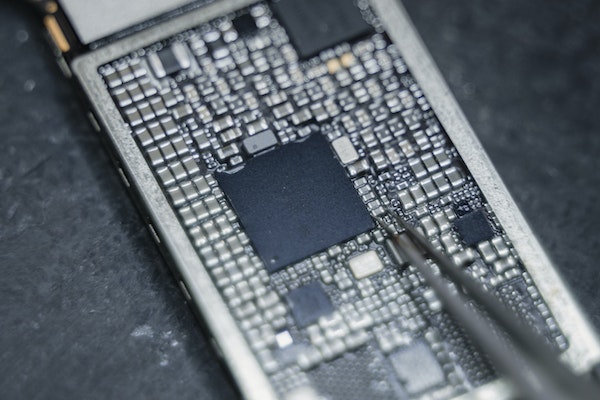

A hot air rework station is a specialized tool used in electronics soldering and rework processes. It combines a heating element and a fan to produce a controlled stream of heated air. The primary purpose of a hot air rework station is to desolder and remove electronic components, such as surface-mounted device (SMD), without causing damage to the surrounding circuit board.

Using a hot air rework station offers several benefits in electronic soldering and rework processes. Firstly, it allows for precise and controlled heating, ensuring that components are desoldered or installed without damaging the surrounding circuit board. The adjustable temperature settings enable compatibility with a wide range of components. Additionally, hot air rework stations offer versatility, as they can be used for tasks such as SMD removal, BGA rework, and PCB preheating. They provide efficiency by reducing the time required for soldering and rework operations. Overall, hot air rework stations improve the quality of work, increase productivity, and are essential tools for electronics repair, manufacturing, and prototyping. Check out:

What are the benefits of using a hot air rework station?

1. Embrace Regular Cleaning:

Regularly clean the nozzles and heating element of your hot air rework station to remove solder residue or debris that may hinder performance. Gently wipe away buildup using a soft brush or cloth, avoiding abrasive materials that could cause damage.

2. Ensure Proper Ventilation:

Maintain adequate ventilation in your workspace to whisk away fumes and smoke generated during operation. Utilize a dedicated fume extractor or position your station near an open window to promote fresh airflow.

3. Check and Replace Filters:

Protect your hot air rework station from harmful particles by checking and replacing filters as recommended. These filters ensure clean air circulation within the station, contributing to a cleaner soldering experience.

4. Inspect and Maintain Connections:

Regularly inspect cables, connectors, and power cords for signs of wear, frayed wires, or loose fittings. Address any issues promptly to ensure safety and maintain optimal performance.

5. Calibrate Temperature Settings:

Periodically calibrate the temperature settings of your hot air rework station for accuracy. Use a reliable thermometer or temperature probe to compare displayed temperature with the actual output. Follow manufacturer's instructions for calibration procedures or seek professional assistance if needed.

6. Store with Care:

When not in use, store your hot air rework station in a clean, dry area. Protect it from dust, moisture, and extreme temperatures. Utilize storage compartments or cases provided to organize and safeguard components.

7. Follow Manufacturer's Guidelines:

Always refer to the manufacturer's instructions for specific maintenance recommendations. Adhere to their guidance diligently to ensure your hot air rework station receives proper care, enhancing its longevity and performance.

By actively maintaining your hot air rework station, you create an environment that promotes optimal performance and longevity. Regular cleaning, proper ventilation, filter replacements, connection inspections, temperature calibration, and careful storage are essential practices. Remember to consult the manufacturer's instructions for specific maintenance guidelines. With your active involvement, your hot air rework station will continue to deliver exceptional results, making your soldering tasks a breeze.

AiXun is a reputable brand known for its high-quality electronic soldering and rework equipment. One of their notable products is the AiXun H310D hot air station. This hot air station is designed to meet the demands of professional soldering and rework tasks. It features a powerful heating element combined with a precision airflow system to deliver consistent and controlled hot air streams. The H310D offers adjustable temperature settings, allowing users to cater to various soldering and rework needs.

WhatsApp

WhatsApp