Oxidation of the soldering iron tip is the most troublesome, because this layer of oxidation on the soldering iron tip is difficult to remove. Many people use sharp tools or sandpaper to "scrape" the soldering iron tip. Although the effect is good for a while, it greatly damages the service life of the soldering iron tip.

Starting from the 80's, iron plating was added to the thermally efficient copper tip, which prevents the copper from dissolving into the solder, thus extending the life of the iron tip. Iron plating on the tip is great for longevity, but it can cause oxidation issues. Tip oxidation occurs when the iron plating on the tip becomes iron oxide. Learn >>>the best material for soldering iron tip made of

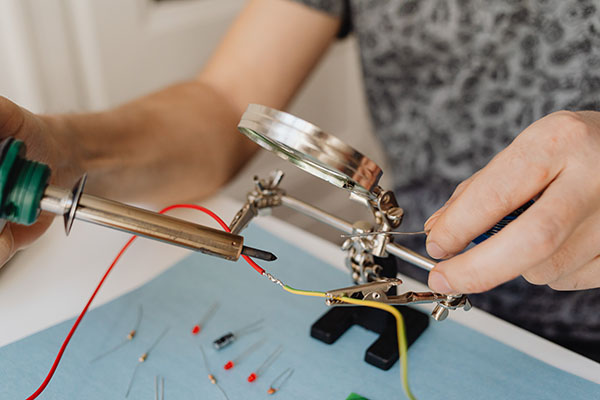

Any soldering iron tip will oxidize to some extent as part of the natural process of iron plating. Any type of buildup will affect soldering performance. If your soldering iron becomes less effective, or if it shows significant oxidation, you should clean the tip to restore the operation.

1. Adjust the temperature of the soldering iron to the typical operating range (approximately 300°C).

2. Apply rosin-containing solder to the oxidized iron tip, the heat activates the flux and starts a chemical reaction that removes the oxidation.

3. Use brass wool or a specially designed cleaner on the tip, the cleaning tool will start to remove the oxide layer.

4. Repeat the above steps until the tip is clean. When cleaned, the tip should appear to allow smooth solder flow. For light oxidation, expect to repeat this process three or four times.

If this process still does not adequately clean the tip, or if the tip is heavily oxidized, you may need to follow the Severely Oxygenated instructions.

Tips for Preventing Oxidation

1. Tin protection after use - every time you finish the work of cleaning the soldering iron , please apply new solder to the tip of the soldering iron. The best oxidation-resistant solder is one with a heavy flux core.

2. Keep the soldering iron tip clean - this is also a way to reduce oxidation. Both a damp sponge and steel wool are effective for cleaning the tip. When cleaning the tip with a damp sponge, keep the tip material flowing and allow the iron to come up to set temperature before wiping again to get the most out of the tip.

3. Avoid high-temperature soldering - if the set temperature is too high, it will accelerate the accumulation of oxidation on the soldering tip, then it will damage the soldering product and shorten the life of the soldering iron tip.

4. Turn it off when not in use - If you won't be doing any soldering for a while, turn off your soldering station. The natural oxidation process occurs much slower at room temperature. There are advanced soldering irons that incorporate an automatic sleep function into their design. These tools automatically turn off the soldering station when not in use, so that extending tip life.

The above is the relevant knowledge about the oxidation of soldering iron tip shared by AiXun precision soldering, I hope it will be helpful to you.

WhatsApp

WhatsApp