When we use the soldering iron for soldering operations, we often encounter the soldering iron tip is not tin, the soldering iron tip is not tin, you can not carry out the soldering operation. If the use of improper and often replace the soldering iron head, this is also a small amount of expenditure. AiXun will explain the reasons why the soldering iron tip does not stick to tin and how to repair the soldering iron tip without sticking to the tin.

The following conditions will cause the soldering iron tip to produce carbide and quickly oxidize the tip, resulting in no tinning.

1. The soldering iron head is under high temperature for a long time.

2. The soldering iron tip should be tinned to protect it at the end of the operation.

3. Contact with plastic parts in the welding process is not cleaned in time.

4. Scrub the soldering iron tip on a dry or unclean sponge or cloth.

5. Whether the soldering iron tip is covered with carbonized flux.

6. Bad plating or solder or unclean soldering surface.

1. The temperature of the soldering station down to 280 °C or so, the soldering iron head on a damp sponge repeatedly wiped and uninterrupted on the new tin protection, repeat the above actions until the lead-free soldering iron head bright tin.

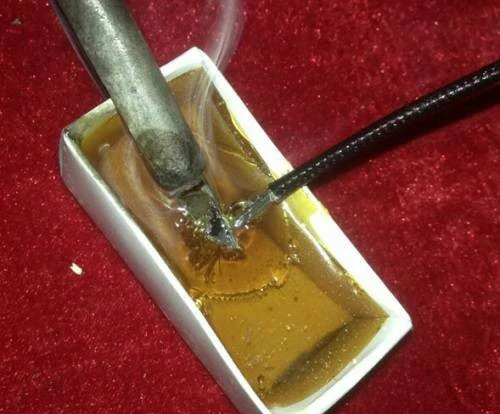

2. Turn off the power supply of the soldering iron, use a razor blade or fine sandpaper to polish off the dirt and oxides on the tinned surface of the soldering iron, and then put the head of the soldering iron into the rosin or rosin paste, turn on the power supply of the soldering iron, adjust the temperature to 280 °C or so, so that the head of the soldering iron is heated up in the rosin, and then use the soldering wire to solder the head of the soldering iron on the tin, tin on the tin, and then look for a strand of copper wire or suction line, so that the head of the iron in the copper parts of the wire to repeat the friction until soldering tin The whole iron is full of solder.

3. Adjust the temperature of the soldering iron to 300-360 °C, insert the special soldering iron head repair paste, wait a few seconds and then use the soldering wire to tin the soldering iron head.

The above is how to fix the soldering iron without tin, hope it helps. AiXun is the best manufacturer & supplier in China for precision soldering tools, accessories and consumables. Welcome to inquiry or visit.

WhatsApp

WhatsApp