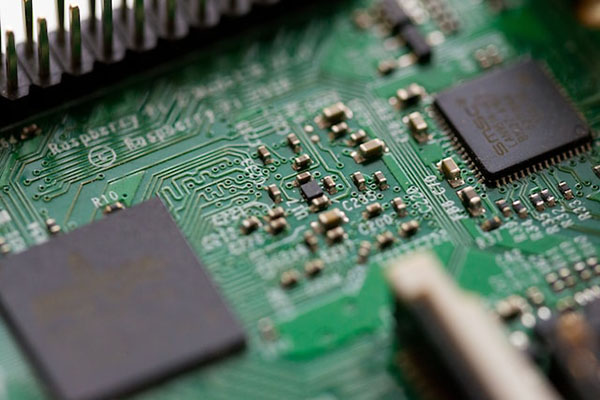

Soldering electronics is a fundamental skill for any electronics enthusiast, hobbyist, or professional. Whether you are repairing a broken circuit board or building your DIY projects, mastering the art of soldering is crucial. This comprehensive guide will walk you through everything you need to know about soldering electronics, from the basics to advanced techniques, safety tips, and essential soldering tools. Let's dive in!

Soldering is a technique used to join two or more electronic components together. It involves melting a metal alloy called solder, which typically consists of a mix of tin and lead (although lead-free alternatives are also available), to create a strong and conductive bond. The solder forms a bridge between the components, ensuring electrical continuity.

Before you start soldering, it's essential to gather the right tools for the job. The basic soldering toolkit includes:

Soldering Iron: A soldering iron is the primary tool used to heat the solder and make the connections. Choose a soldering iron with adjustable temperature settings for versatility.

Solder: Select a high-quality solder with the appropriate composition for your project, such as leaded or lead-free solder.

Soldering Stand: A stand to hold the soldering iron when not in use, preventing accidental burns and damage.

Soldering Tip Cleaner: Keep your soldering tip clean to ensure better heat transfer and longer tip life.

Desoldering Pump or Solder Wick: These tools are used to remove excess solder or correct mistakes.

Prepare the Components: Trim component leads to an appropriate length and ensure the parts fit neatly on the circuit board.

Heating the Joint: Place the soldering iron's tip against the joint where the component lead and circuit board meet. Allow the joint to heat for a few seconds.

Applying Solder: Once the joint is heated, touch the solder to the joint's opposite side, allowing it to flow evenly and cover the joint entirely.

Cooling: Allow the joint to cool naturally without disturbing it. Moving the joint too early can result in a weak connection.

Safety Tips

Safety is paramount when soldering electronics. Follow these safety tips to protect yourself and your workspace:

1. Work in a well-ventilated area to avoid inhaling fumes from the solder.

2. Wear safety glasses to shield your eyes from solder splatters and other debris.

3. Keep your workspace tidy and organized to prevent accidental burns or damage to components.

4. Always turn off and unplug your soldering iron when not in use.

Even seasoned soldering experts encounter challenges. Some common issues and troubleshooting tips include:

Cold Joints: Insufficient heat or improper soldering technique can result in cold joints. Reheat the joint and apply fresh solder.

Solder Bridges: Excess solder can cause solder bridges where connections are unintentionally connected. Use desoldering tools to remove the excess solder carefully.

Soldering electronics may seem intimidating at first, but with practice and proper guidance, anyone can master this essential skill. From understanding the basics to handling more complex projects, this comprehensive guide has equipped you with the knowledge you need to solder electronics confidently and effectively. So, get your soldering iron ready and start bringing your electronic creations to life! Happy soldering!

WhatsApp

WhatsApp