Soldering is a process of joining two metal surfaces together using a filler material, usually a lead-tin alloy. It is a skill that is used in a variety of applications, from electronics to plumbing.

Soldering wires is a skill anyone can learn with ease. No special talents are required—just gather basic equipment and devote some time to practice.

Ensure sure your workspace is adequately ventilated, especially if you're using lead-based solder. Work on a non-flammable surface because molten solder can drip from soldering iron tips, which can reach temperatures of 600 to 800 degrees Fahrenheit. Wash your hands thoroughly after handling lead-based solder if you are using it.

Soldering iron/station: Make sure you have a soldering iron with the right wattage for the wire size.

Flux Paste: Flux paste is used in wire soldering to clean the surfaces of the wires and improve solder adhesion.

Solder: The 63/37 solder, composed of 63% tin and 37% lead alloy, is widely regarded as the easiest solder to work with.

Wire strippers: Use these to remove insulation from the wire ends.

Heat-resistant surface: Heat-resistant surface: Find a safe spot to place your soldering iron when not in use, if you use a soldering station, it will contain the stand already.

Hot air gun: A hot air gun, also known as a heat gun, blow a stream of hot air

Prepare the wires:

Strip the insulation: Use wire strippers to expose a small section of bare wire at the ends you want to join. About half an inch should be enough.

Clean the wires: If the wires are dirty or have any oxidation, give them a gentle cleaning using a wire brush or sandpaper. You want the wire ends to be clean and shiny.

Twist the wires together:

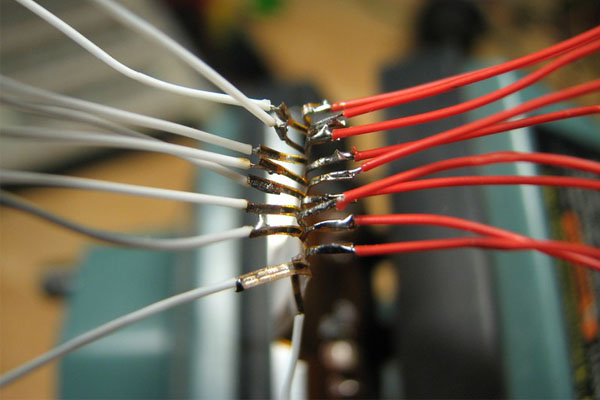

Align the stripped ends: Place the stripped ends of the wires side by side.

Twist the wires: Hold the wires firmly and twist them together in a clockwise direction. The twisting helps create a sturdy connection.

Heat the wires:

Heat up the soldering iron: Plug in your soldering iron and let it heat up to the appropriate temperature for the solder you're using.

Apply heat: Gently touch the tip of the soldering iron to the twisted wire joint. Make sure the heat is evenly distributed across the joint without overheating it.

Apply solder:

Touch the solder, not the iron: Take the solder wire and touch it to the joint—not the soldering iron tip.

Let it flow: As the wires heat up, touch the solder wire to the joint. The heat should melt the solder, allowing it to flow around the wires. Apply just enough solder to cover the joint without excess buildup.

Let it cool:

Remove the soldering iron: Once you're satisfied with the solder flow, remove the soldering iron.

Keep it steady: Hold the joint steady and avoid moving or bending it until the solder cools and solidifies. This ensures a strong bond.

Insulate the joint:

Protect the connection: Once the solder has cooled down, use electrical tape, heat shrink tubing, or another insulating material to cover the joint completely. This prevents exposed wires and potential short circuits.

AiXun is a renowned manufacturer of top-quality welding tools and consumables, providing a comprehensive range of products to meet various soldering needs. Our commitment to excellence sets us apart in the industry.

For any inquiries or to explore our offerings, please don't hesitate to contact us at www.aixuntech.com or send us an email at info@aixuntech.com.

WhatsApp

WhatsApp