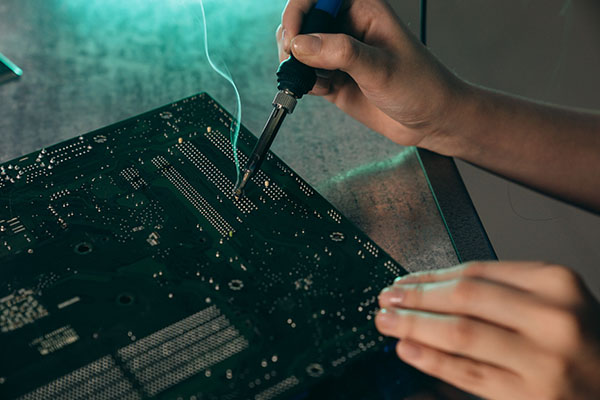

When doing SMT chip processing business, we often encounter such questions, do you use lead-free soldering or leaded soldering? So, what is the difference between lead-free and lead-based soldering? Why should SMT chip processing use lead-free soldering?

1. The difference between leaded and lead-free soldering

Generally speaking:

Soldering with leaded solder paste or lead-free solder paste. Lead-free solder paste is environmentally friendly, and leaded solder paste is not, so the difference between lead and lead-free solder paste in SMT chip processing is environmental protection and non-environmental protection. AiXun environmentally friendly lead-free solder paste flux is suitable for BGA ball planting of electronic, rework, component soldering, repair soldering, etc.

2. The concept of leaded process and lead-free process

Lead-free process: A basic concept of lead-free electronic assembly is that in the soldering process, no matter manual soldering, dip soldering, wave soldering or reflow soldering, the solder used is lead-free solder. Lead-free solder does not mean that the solder is 100% lead-free. In leaded solder, lead exists as an essential element. In lead-free solder, the basic element does not contain lead.

Lead process: In the traditional soldering process of printed circuit board assembly, tin-lead (sn-pb) solder is generally used, in which lead exists and functions as a basic element of solder alloy.

The difference between leaded and lead-free

1. Different alloy composition:

The composition of tin and lead commonly used in lead processing is 63/37

The composition of the lead-free alloy is SAC305,

That is, Sn: 96.5%, Ag: 3% and Cu: 0.5%.

Lead-free processes cannot be absolutely lead-free, but only contain very low levels of lead

2. Different melting points:

The melting point of leaded tin is 180°~185°, and the working temperature is about 240°~250°.

The melting point of lead-free tin is 210°~235°, and the working temperature is 245°~280°.

3. Cost difference:

Tin is more expensive than lead, and when the equally important solder is changed to tin, the cost of the solder also increases. Therefore, the cost of lead-free processing is much higher than that of leaded processing.

The cost of lead-free processing is 2.7 times the cost of leaded processing for wave soldering and manual soldering, and about 1.5 times the cost of solder paste for reflow soldering.

Why use lead-free soldering for SMT chip processing?

Now is the time to summarize this issue. Lead-free soldering is mainly for environmental protection. It is healthier for users and the impact on the environment will be greatly reduced. However, the cost of lead-free soldering will be higher, so the unit price of chip processing will also be higher. Customers need to use lead-free or leaded soldering, which should be considered according to the product's use environment, product price and profit, rather than blindly pursuing lead-free soldering.

Follow AiXun, we update daily!

Reading more >>>>>

WhatsApp

WhatsApp