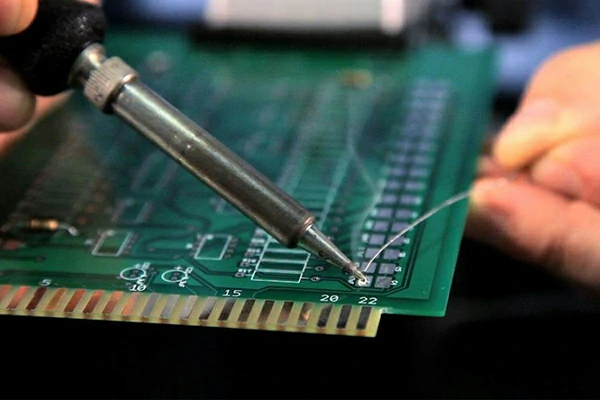

A soldering station is an indispensable tool for electronics enthusiasts, hobbyists, and professionals alike. It provides the necessary heat control and stability required for soldering and desoldering operations. However, like any equipment, soldering stations have a finite lifespan. You may have some questions for your soldering station. When it starts to stop working? Will it stop turning on? Overheat? Light on fire?

Here, AiXun will delve into the factors that influence the lifespan of a soldering station and discuss essential maintenance practices to extend its longevity.

Quality of Construction:

The quality of construction plays a significant role in determining the lifespan of a soldering station. Stations made with durable materials, such as high-grade plastics and metal components, are likely to last longer than those made with cheaper and less robust materials.

Frequency and Intensity of Use:

The frequency and intensity of use directly impact the lifespan of a soldering station. Continuous and heavy usage can subject the heating element, soldering iron, and other components to excessive wear and tear. It is important to consider the duty cycle and temperature rating of the station to ensure it can handle the expected workload.

Maintenance and Cleaning:

Proper maintenance and regular cleaning are crucial for prolonging the lifespan of a soldering station. Accumulated flux, solder residue, and other contaminants can affect the performance and functionality of the station over time.

Temperature Control and Calibration:

Accurate temperature control is vital for precise soldering and the longevity of a soldering station. Excessive temperature fluctuations or inaccurate temperature readings can strain the heating element and thermocouple.

Proper Storage:

When not in use, storing the soldering station correctly is crucial. Protecting it from dust, moisture, and physical damage will help prevent premature degradation.

You should consider the following factors when determining when to replace a soldering station:

Performance Issues: If you notice a decline in the performance of your soldering station, such as difficulty in maintaining a consistent temperature, fluctuating heat output, or a slow response to temperature adjustments, it might be a sign that internal components are wearing out.

Worn-out Tips: Soldering iron tips are consumable parts that wear out over time. If you find it increasingly difficult to keep your tips clean or if they are not transferring heat effectively, it may be time to replace them. Some stations allow you to replace just the tips, while others may require replacing the entire iron.

Unreliable Temperature Control: Inaccurate temperature control can lead to poor solder joints and component damage. If your soldering station's temperature control becomes inconsistent or unreliable, it may be a sign that the temperature sensor or control circuitry is failing.

Visible Signs of Wear: Inspect your soldering station for any visible signs of wear or damage. This includes frayed power cords, loose connections, or damaged housing. Addressing these issues promptly can prevent further damage and extend the life of your equipment.

Obsolete Technology: If your soldering station uses outdated technology or lacks features that are now essential for your work, it might be worth considering an upgrade to a more modern model that meets your current requirements.

Frequency of Calibration: Some soldering stations require periodic calibration to ensure accurate temperature readings. If your station frequently needs calibration, it may indicate underlying issues with its internal components.

Availability of Replacement Parts: Check if replacement parts for your soldering station are readily available. If the manufacturer no longer supports your model or if it's challenging to find replacement components, it may be a sign to consider upgrading to a newer model.

To extend the lifespan of a soldering station, consider the following tips:

1. Invest in a high-quality soldering station from reputable brands known for their durability and performance. Quality construction materials and components will ensure a longer lifespan.

2. Follow the manufacturer's guidelines for temperature settings, duty cycle, and recommended usage. Avoid exceeding the station's temperature limits or subjecting it to excessive use beyond its capacity.

3. Use accurate temperature control and calibration. Regularly calibrate the temperature settings using a reliable thermometer or temperature probe to ensure precise soldering and prevent strain on the heating element.

4. Regularly clean the soldering iron tip and station to remove flux, solder residue, and contaminants. Replace worn-out parts as needed, and ensure optimal airflow and heat dissipation. Adhere to the manufacturer's maintenance instructions.

5. Handle the soldering iron and station with care to prevent physical damage. Avoid dropping or mishandling the equipment, which can cause internal damage or component failure.

6. When not in use, store the soldering station in a clean and dry environment. Protect it from dust, moisture, and physical damage by using dedicated cases or covers.

7. Turn off the soldering station when not in use for an extended period. Power cycling helps reduce unnecessary wear on the heating element and other components.

8. Minimize unnecessary heat-ups by turning off the soldering station during breaks or when not actively soldering. Frequent and unnecessary heat-ups can contribute to component degradation.

9. Select appropriate soldering iron tips for different soldering tasks. Using the correct tip for specific applications ensures efficient heat transfer and reduces strain on the station.

10. Periodically inspect the soldering station for any signs of wear, loose connections, or damage. Address any issues promptly to prevent further damage or compromised performance.

If you want your soldering station to last longer and work reliably, there are a few things to keep in mind. First, choose a good-quality station from a trusted brand. Take care of it by cleaning it regularly and following the instructions for how to use it. By doing these things, you can make sure your soldering station will serve you well for many years, allowing you to solder and desolder with ease.

WhatsApp

WhatsApp