A constant temperature soldering iron, also known as a temperature-controlled soldering iron, is a specialized tool used for soldering electronic components and other materials. Unlike basic soldering irons that have a fixed temperature, constant temperature soldering irons allow you to precisely control the temperature of the soldering tip.

There are not many types of constant temperature electric soldering irons, and the simple temperature control circuit is installed in the handle of the soldering iron. The more complex structure is called a soldering station, and its soldering iron core adopts PTC heating element. After changing the set temperature, the soldering iron tip can quickly reach the new set temperature.

1. The electric soldering iron should be grounded; check whether the power is normal, (after the constant temperature type soldering iron is energized, the power indicator light flashes, and the temperature is constant when it is always on; the external heat type conventional soldering iron is energized for 1 minute, and then the tip of the soldering iron is energized if it is hot to breathe)

2. After the electric iron is energized, it is not allowed to arbitrarily knock, disassemble and install its electric heating parts;

3. The electric soldering iron should be kept dry and should not be used in an excessively humid or rainy environment;

4. When removing the soldering iron head, turn off the power supply;

5. After turning off the power and when leaving, put a layer of tin on the tip of the soldering iron to protect the tip of the soldering iron;

6. When there is a black oxide layer on the tip of the soldering iron, it can be wiped off with emery cloth, then powered on and tinned immediately;

7. The sponge is used to collect tin slag and tin beads, and it is enough to squeeze it by hand just enough to get no water;

8. Clean before soldering, and keep the workstation clean after soldering.

1. The temperature is determined by the actual use, and it is most suitable to solder a tin point for 3S. Usually observe the tip of the soldering iron, when it turns purple, the temperature is set too high.

2. Generally, for straight-in electronic materials, set the actual temperature of the soldering iron head to (330-370 degrees Celsius); for surface mount materials (SMT) materials, set the actual temperature of the soldering iron head to (300-320 degrees Celsius)

3. For special materials, the temperature of the soldering iron needs to be specially set. For example, the soldering temperature of sensitive electronic components (crystals, LED lights) is between 300 and 350 degrees Celsius.

4. When soldering large component feet (such as USB interface, SATA interface, IDE), the temperature should not exceed 400 degrees Celsius, and the soldering time should not be too long, so as not to damage the pads.

1. Hot tin repair soldering should follow the order from left to right and top to bottom to avoid missed inspection during inspection or missed repair during soldering.

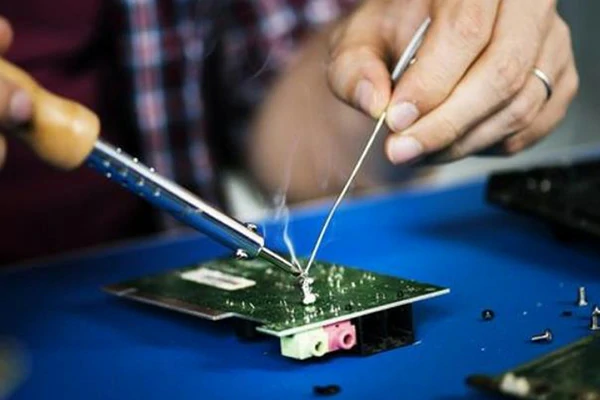

2. The soldering iron tip should be cleaned frequently during soldering to prevent the occurrence of defects such as false soldering, pinholes, and false soldering caused by the debris of the soldering iron tip.

3. Do not add soldering tin to the soldering iron tip on the substrate. During the production process, do not shake, knock, or throw tin to prevent solder slag and solder beads from falling onto the substrate.

4. When pressing or disassembling parts, solder should be added to the copper foil surface of the circuit board first, and uniform heating is required to avoid circuit damage caused by rosin failure or copper foil warping.

1. Tools: brush, white cloth, washing water;

2. First, wash the brush with washing water, and then use the brush to clean the rosin on the tin point;

3. Be careful not to use too much wash water and do not flow to other locations, especially sockets, plugs and switches.

When it comes to precision and quality in soldering, look no further than AiXun! We're thrilled to be your go-to soldering solution expert, offering cutting-edge technology and expertise that make your soldering tasks a breeze. Business inquiry: info@aixuntech.com or contact through the official website.

WhatsApp

WhatsApp