Soldering circuit boards requires a delicate touch and the right tools to ensure clean, reliable connections. Central to this process is selecting the best soldering iron station for the job.

When it comes to soldering circuit boards, you'll want a soldering iron that is precise, temperature-controlled, and has a fine tip. Here are some features to consider when choosing the best soldering iron for circuit boards:

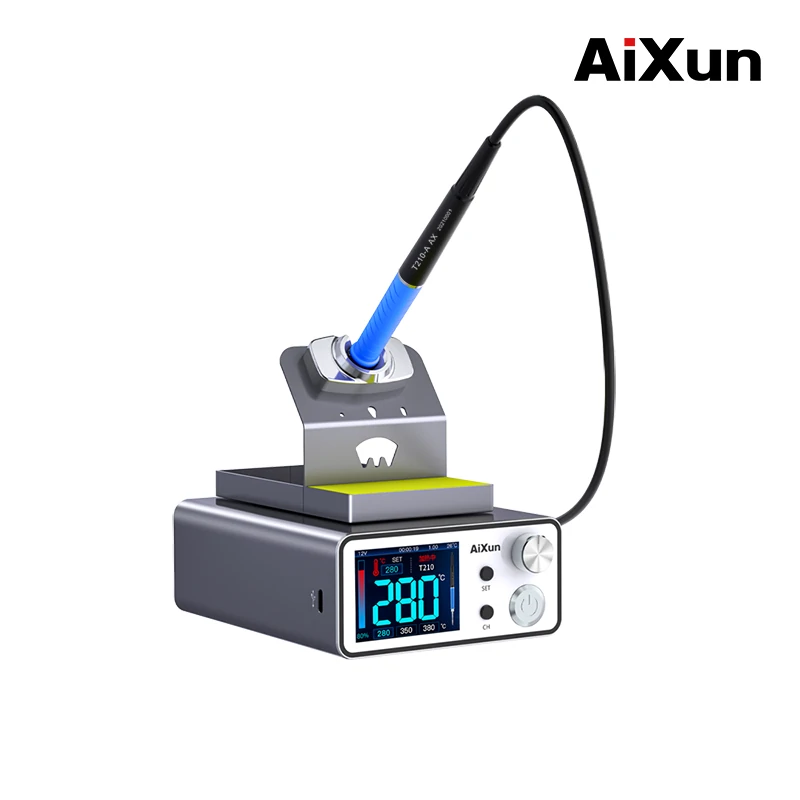

Temperature Control: Look for a soldering iron with adjustable temperature settings. Different components and solder types require different temperatures for proper soldering.

Wattage: For soldering small components on circuit boards, a lower wattage soldering iron is generally recommended. Higher wattage irons are better for larger projects, but they can be too hot and potentially damage delicate components on circuit boards.

Fine Tip: A soldering iron with a fine, conical or chisel-shaped tip is essential for precision work on circuit boards. The tip should be easily replaceable as well.

ESD-Safe: An ESD-safe soldering iron is designed to prevent electrostatic discharge, which can damage sensitive electronic components. This is crucial for working on circuit boards.

Quality and Brand: Invest in a reputable brand known for producing reliable soldering equipment. Brands like Weller, Hakko, Metcal and AiXun are well-regarded in the electronics industry.

Comfort and Ergonomics: Consider the comfort and ergonomics of the soldering iron's handle, especially if you plan to use it for extended periods.

For soldering on a circuit board, you should use rosin-core solder (also known as flux-core solder), specifically designed for electronics and electrical work. Rosin-core solder is the most common type of solder used in electronics because it combines the soldering material (usually a mix of tin and lead or a lead-free alternative) with a flux core.

Here are some key points to consider when choosing the right solder for circuit board work:

Lead vs. Lead-Free Solder: You have the option of using lead-based solder (typically 60/40 or 63/37, referring to the tin/lead ratio) or lead-free solder, depending on your environmental and regulatory considerations. Lead-free solder is becoming more common due to environmental regulations, but it can be slightly more challenging to work with and requires higher soldering temperatures.

Diameter: Solder comes in various diameters (e.g., 0.8mm, 1mm, 1.5mm). For most circuit board work, a thinner diameter, such as 0.8mm or 1mm, is recommended because it allows for more precise control and reduces the risk of creating solder bridges between closely spaced components.

Flux Core: The rosin core in the solder provides flux, which is essential for cleaning the surfaces being soldered and promoting proper solder flow. It's important to have the right amount of flux to ensure reliable solder joints. Excessive flux can be detrimental, so choose solder with an appropriate flux core.

No-Clean Solder: Some modern solder options are labeled as "no-clean" solder. These solders contain a flux that leaves behind minimal residue, reducing the need for post-solder cleaning. This can be convenient for many electronics projects, but it's essential to follow manufacturer recommendations.

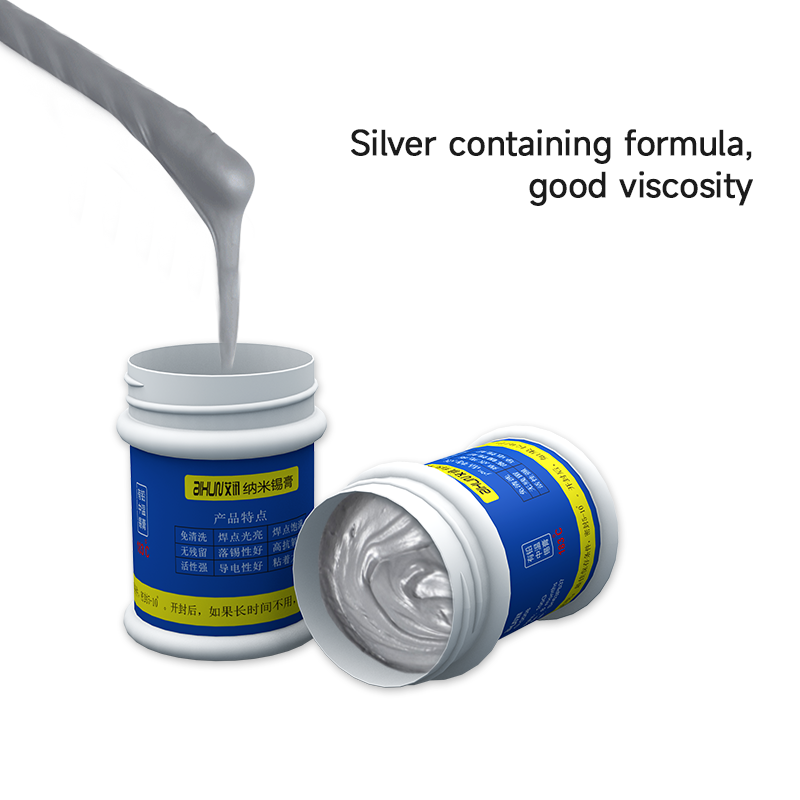

Soldering Flux is highly recommended when soldering circuit boards, as it plays a crucial role in achieving reliable and clean solder joints. Flux serves several essential purposes in the soldering process:

Deoxidizing and Cleaning: Flux helps remove oxides and impurities from the surfaces of the metal components being soldered, such as the leads of electronic components and the copper traces on the circuit board. This cleaning action ensures that the solder can bond properly to the surfaces.

Enhancing Wetting: Flux promotes the even spreading (wetting) of molten solder over the surfaces to be joined. It helps the solder flow smoothly and create a strong, uniform bond.

Preventing Oxidation: During the soldering process, high temperatures can cause metal surfaces to oxidize quickly. Flux acts as a protective barrier, preventing further oxidation while the soldering takes place.

Reducing Solder Bridges: Flux helps prevent the formation of solder bridges, which are unintended connections between adjacent traces or pins on a circuit board.

In summary, flux is crucial for circuit board soldering due to its multifunctional role in achieving clean, reliable solder joints.

WhatsApp

WhatsApp