Soldering irons are the most common tool used for soldering. Soldering is a crucial process in many industries, from electronics manufacturing to metalworking. It is a process that requires precision and skill, and the right tools are essential for achieving the best results. Having the right tips is essential for getting the best results every time.

The most important factor to consider when selecting a soldering iron tip is the material of the tip. Copper is the most common material used for soldering iron tips, as it is highly durable and can withstand high temperatures. Copper is also a good conductor of heat, which makes it ideal for soldering. Other materials used for soldering iron tips include nickel-plated steel, stainless steel, and tungsten.

The shape of the soldering iron tip is also important. The most common shapes are chisel, conical, and pointed. Chisel tips are flat and wide, making them ideal for soldering large surfaces. Conical tips are more narrow and pointed, making them better for soldering small components. Pointed tips are the most precise, and are often used for detailed work.

The size of the soldering iron tip is also important. The size of the tip should be chosen based on the size of the components being soldered. Smaller tips are better for soldering small components, while larger tips are better for soldering larger components.

When using a soldering iron, it is important to use the correct temperature. The temperature of the soldering iron should be set according to the type of material being soldered. Different materials require different temperatures, and the temperature of the soldering iron should be adjusted accordingly. It is also important to make sure that the soldering iron is not overheated, as this can damage the components being soldered.

When soldering, it is important to use the correct flux. Flux is a substance that helps the solder flow more easily and prevents oxidation. Different types of flux are available, and the type of flux used should be chosen based on the type of material being soldered.

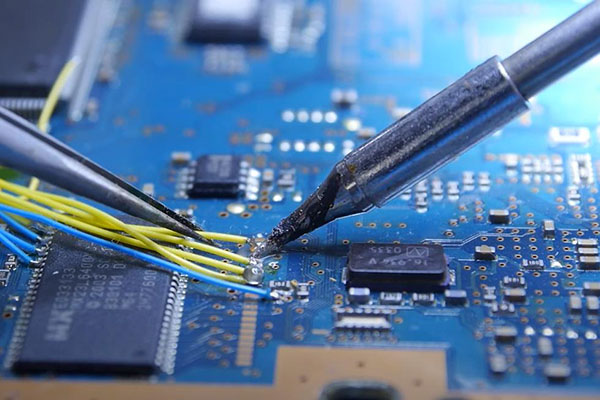

When soldering, it is important to use the correct technique. The soldering iron should be held at a 45-degree angle to the component being soldered, and the solder should be applied in a circular motion. The solder should also be applied from the outside of the component to the inside.

Finally, it is important to maintain the soldering iron tip. Soldering iron tips should be cleaned regularly to remove any build-up of flux or oxidation. The tip should also be inspected for any damage, such as cracks or chips.

By following these tips, you can ensure that you get the best results every time when soldering. With the right tools and techniques, soldering can be a precise and efficient process.

AiXun soldering iron station manufacturer was founded in 2018 and supplies a big selection of soldering tools such as soldering station, soldering irons, desoldering station, SMD rework station, JBC soldering iron tips and consumables, etc. With over years experience of solder station manufacturing, AiXun soldering equipment supplier provides high performance, high quality and competitive prices of solder stations. AiXun sincerely welcomes your inquiries and cooperation.

WhatsApp

WhatsApp