To truly grasp the disparities between soldering stations and soldering irons, let's break down the key distinctions between these essential soldering tools. Soldering station Vs. Soldering iron

Temperature Control:

Soldering Station: Offers precise temperature control, allowing users to set and maintain specific soldering temperatures. This is vital for delicate electronic work and ensures consistent results.

Soldering Iron: Typically relies on wattage-based temperature control, offering less precision and the potential for temperature fluctuations during use.

Versatility:

Soldering Station: Highly versatile due to adjustable temperature settings and interchangeable tips. Suitable for a wide range of soldering tasks, from intricate electronics to larger projects.

Soldering Iron: Versatile but may have limitations due to fixed tips and less precise temperature control. May require separate soldering irons for different applications.

Stability:

Soldering Station: Engineered for stability, maintaining a constant temperature throughout the soldering process. Reduces the risk of temperature fluctuations affecting soldering quality.

Soldering Iron: May experience temperature fluctuations, potentially impacting soldering consistency, especially in prolonged use.

Safety Features:

Soldering Station: Often equipped with safety features such as auto-off timers and overheat protection, enhancing safety during soldering tasks.

Soldering Iron: Requires constant user vigilance to prevent overheating. Generally lacks the same level of built-in safety mechanisms as soldering stations.

Precision:

Soldering Station: Provides the precision needed for delicate electronic components and soldering tasks that demand accurate heat control.

Soldering Iron: Offers versatility but may not meet the precision requirements of certain applications.

Ease of Use:

Soldering Station: May have a steeper learning curve due to advanced temperature control but provides more consistent results once mastered.

Soldering Iron: Generally straightforward to use and suitable for beginners. However, achieving consistent results may require more practice.

Cost:

Soldering Station: Often comes at a higher initial cost due to its advanced features and capabilities.

Soldering Iron: Typically more budget-friendly, making it an accessible option for those starting with soldering projects.

While both soldering stations and soldering irons have their unique strengths and applications, their differences lie primarily in temperature control precision, versatility, stability, safety features, and cost. Understanding these distinctions is essential for selecting the right tool for your specific soldering needs, whether you're working on intricate electronics or tackling larger soldering projects.

Understanding the typical use cases for soldering stations and soldering irons is crucial for choosing the right tool for your specific soldering needs. Let's explore scenarios where each tool excels and practical examples of when one might be preferred over the other:

Soldering Stations:

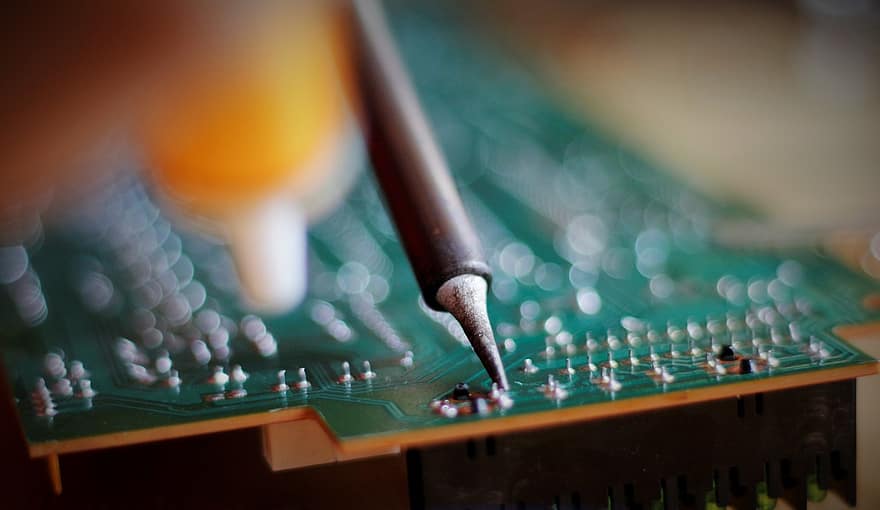

Electronics and Circuitry: Soldering stations are ideal for precision work on delicate electronic components, circuit boards, and surface-mount devices. Their precise temperature control ensures that sensitive parts are not damaged by excessive heat. Examples include soldering microcontrollers, resistors, and integrated circuits.

Temperature-Sensitive Materials: When working with temperature-sensitive materials like heat-sensitive plastics or thermocouples, soldering stations are the preferred choice. The ability to set and maintain precise temperatures minimizes the risk of material damage.

Consistent Production Environments: In manufacturing or production settings where consistency and quality control are essential, soldering stations are favored. They offer stable and uniform results, making them suitable for high-volume production of electronic devices.

Soldering Irons:

General Soldering Tasks: Regular soldering irons are versatile and suitable for a wide range of general soldering tasks, including soldering wires, connectors, and through-hole components on PCB.

Plumbing and HVAC Work: Soldering irons are commonly used in plumbing and HVAC (heating, ventilation, and air conditioning) applications for joining copper pipes and fittings. These tasks do not require the precision temperature control of soldering stations.

Quick Repairs: For quick, on-the-spot repairs or DIY projects, a soldering iron provides a convenient and portable solution. Examples include fixing broken cables, soldering connectors, or crafting simple electronic projects.

Educational Use: Soldering irons are often recommended for beginners and educational settings due to their simplicity and affordability. They provide a practical introduction to soldering techniques and can be used in school labs or maker spaces.

Scenarios Where One Tool Is Preferred:

Soldering Station: When working on intricate electronics, temperature-sensitive materials, or in professional manufacturing environments where precision and consistency are paramount.

Soldering Iron: For general soldering tasks, quick repairs, plumbing, DIY projects, or educational purposes where simplicity and affordability are key factors.

Ultimately, the choice between a soldering station and a soldering iron depends on the specific soldering task at hand, the materials being worked with, and the level of precision and control required. Having both tools available can provide versatility for tackling a wide range of soldering projects.

Ready to start your soldering project? Explore our comprehensive resources, articles, and product guides to enhance your soldering skills and discover the tools that best suit your projects. Clicking the links below to access additional valuable content and product recommendations:

Link to Soldering Station vs. Soldering Iron: Key Differences Explained

Browse Soldering Stations

View More Soldering Tips and Techniques on AiXun Website.

Thank you for joining us on this exploration of soldering stations and soldering irons. We look forward to being your trusted source for soldering knowledge and tools on your soldering adventures.

WhatsApp

WhatsApp