Soldering is an art, and like any craft, it requires the right tools to achieve perfection. Whether you're a hobbyist, DIY enthusiast, or a professional in the field of electronics, having control over your soldering temperature can make a world of difference. This article will delve into the world of temperature controlled soldering stations, explaining their significance, how they function, the wide range of temperatures they offer, and why they are indispensable for your soldering projects.

A temperature controlled soldering station is an advanced soldering tool designed to provide precise temperature regulation for your soldering iron. Unlike conventional soldering irons with fixed temperatures, these stations allow you to adjust and maintain the iron's temperature according to the specific soldering requirements of your project.

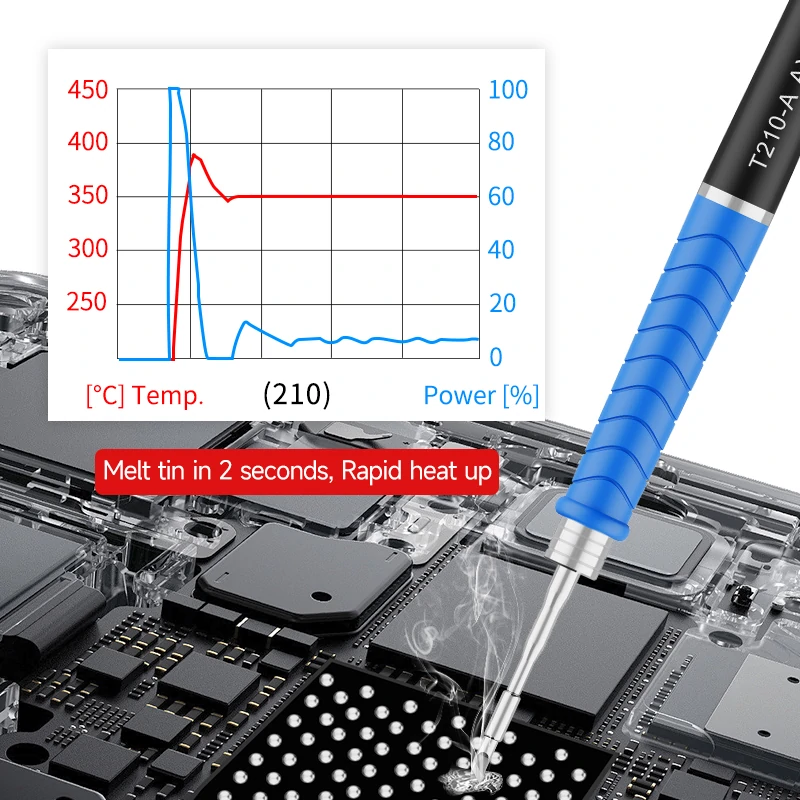

These stations typically consist of a soldering iron with a built-in temperature sensor, a digital temperature display, and user-friendly controls. The digital display allows you to set your desired temperature, and the internal components, such as a microcontroller or PID (Proportional-Integral-Derivative) system, work diligently to regulate the heating element, ensuring that the selected temperature is maintained accurately.

Controlling the temperature of a soldering station is a breeze, thanks to its user-friendly design. Most modern soldering stations feature a digital temperature display and intuitive controls. Here's how it works:

Setting the Temperature: Start by powering on the soldering station and using the control buttons to select your desired temperature. The digital display provides real-time feedback, allowing you to see the temperature rise to your chosen level.

Temperature Regulation: Once you've set the temperature, the station's internal components take over. They continuously monitor the temperature, making small adjustments as needed to ensure it remains precisely where you want it.

This level of control empowers you to tailor the temperature to the specific solder and materials you're working with, ensuring optimal results for every project.

The adjustable temperature range of a soldering iron station can vary from model to model, but most quality stations offer a wide temperature spectrum to accommodate a variety of soldering tasks. The temperature range typically spans from as low as 100°C (212°F) to well over 500°C (932°F). This extensive range is particularly advantageous because it allows you to work with different materials and components effectively.

For example, delicate electronics may require a lower temperature to prevent damage, while larger soldering tasks may necessitate higher temperatures for efficient solder flow. Having the flexibility to choose the appropriate temperature for each job is a significant advantage that these stations provide.

The decision to invest in a temperature controlled soldering station hinges on the nature and precision requirements of your soldering projects. Here are some factors to consider:

Project Complexity: If your soldering projects involve intricate tasks such as electronics assembly, circuit board work, or precision soldering, a temperature controlled station is highly beneficial. It allows you to fine-tune the temperature to match your solder and materials, preventing damage and ensuring professional-grade results.

Versatility: Temperature controlled soldering stations offer versatility. They are suitable for a wide range of soldering tasks, from intricate micro-soldering to more extensive soldering jobs. If you work on a variety of projects, having a temperature controlled station can streamline your workflow.

Consistency: These stations provide consistent and reliable temperature control. This consistency is essential for achieving reliable solder joints, especially in projects where precision and quality are paramount.

Environmental Responsibility: Many temperature controlled soldering stations are designed to use non-toxic lead-free solder wire, which is environmentally friendly. This choice aligns with modern environmental standards and ensures a safe soldering experience for you and the planet.

While a temperature controlled soldering station may represent a more significant investment than a basic soldering iron, its advantages in terms of precision, versatility, and consistency make it a worthwhile choice for those who are serious about achieving high-quality solder joints.

In the world of soldering, precision and control are essential for achieving professional results. A temperature controlled soldering station empowers you to achieve consistent, precise, and reliable solder joints with ease. By understanding what it is, how to use it, the temperature range it offers, and when to use it, you can make an informed decision about adding this invaluable tool to your soldering arsenal.

Whether you're a seasoned professional or just embarking on your soldering journey, a temperature controlled soldering station is a game-changing investment that will elevate your soldering skills and ensure that every solder joint meets the highest standards of quality and precision.

For the most up-to-date information on AiXun Temperature Controlled Soldering Stations, pls visiting AiXun official website or contacting the customer support. They will provide you with the latest details on budget soldering station lineup.

WhatsApp

WhatsApp