Soldering station is a indispensable tool for anyone involved in electronics, DIY projects, or professional soldering work. Understanding the basics of soldering stations is essential for achieving optimal results. In this article, we will cover the fundamental information you need to know about soldering stations, including their components, functions, and suitability for beginners.

Soldering is a technique used to join metal components using solder, a metal alloy with a low melting point. It involves heating the solder to its melting point and applying it to the joint, creating a strong bond as it solidifies. Soldering is widely used in electronics, jewelry making, plumbing, and other industries. It enables the connection of wires, components, and pipes, providing both electrical conductivity and mechanical strength. With the right tools and techniques, soldering allows for precise and reliable connections, making it an essential skill for various applications.

A soldering station is a complete soldering system that typically consists of a soldering iron, a temperature control unit, and various accessories. The soldering iron generates heat to melt solder and join components, while the temperature control unit regulates and maintains the desired temperature for precise soldering.

A soldering station typically consists of several components that work together to provide controlled heat for soldering tasks. The main components of a soldering station include:

Soldering Iron: The soldering iron is the handheld tool used to apply heat to the workpiece and melt solder. It consists of a heating element and a replaceable soldering tip. The tip is the part that directly contacts the components and transfers heat for soldering.

Temperature Control Unit (Power Station or Base Station): The temperature control unit regulates and maintains the desired temperature of the soldering iron. It typically features a digital or analog interface that allows users to adjust the temperature according to their specific soldering requirements. The temperature control unit provides a stable and controlled heat source for consistent soldering results.

Accessories: Soldering stations often come with various accessories to enhance usability and convenience. These accessories may include:

Stand or Holder: A stand or holder provides a safe place to rest the soldering iron when not in use. It keeps the soldering iron upright and stable, preventing accidental burns or damage to surfaces.

Cleaning Sponge or Brass Wire Tip Cleaner: A cleaning sponge or brass wire tip cleaner is used to remove excess solder and clean the soldering tip. It helps maintain a clean and functional tip for optimal soldering performance.

Tip Maintenance Tools: Tip maintenance tools, such as soldering tip tinner or cleaner, can be used to reshape or clean the soldering tip, extending its lifespan and ensuring efficient heat transfer.

Additional Features: Some soldering stations may include additional features, such as programmable presets for storing temperature settings, integrated lighting for better visibility, or compatibility with specialized tips for specific soldering applications.

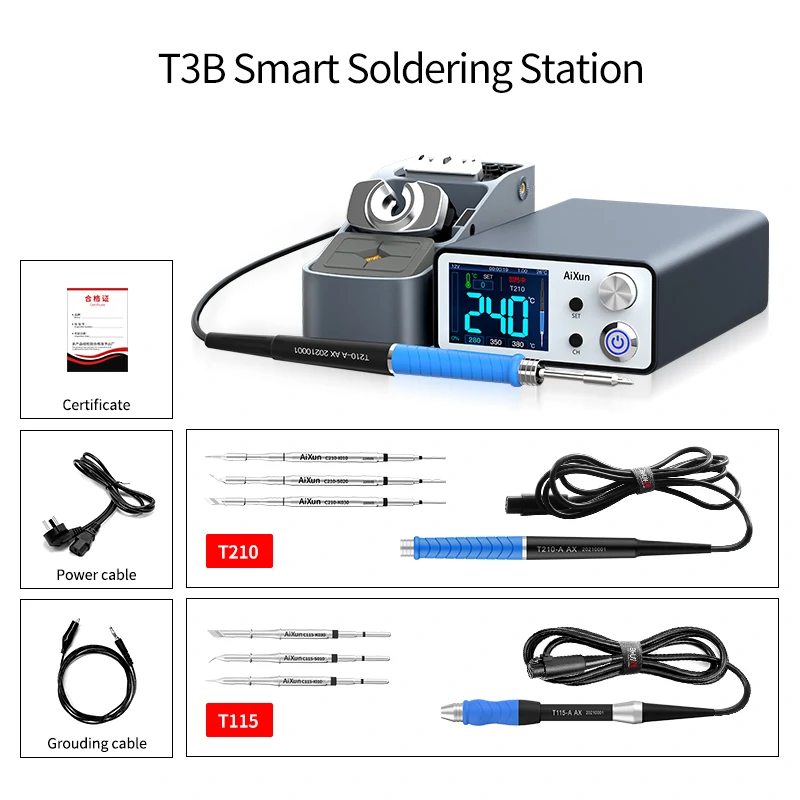

These components work together to provide precise temperature control, stable heat output, and convenience during soldering tasks. The soldering iron generates the heat, the temperature control unit regulates it, and the accessories aid in maintenance and usability. By utilizing the components of a soldering station effectively, users can achieve accurate and reliable soldering results. Check out AiXun T3B soldering station for example.

A soldering station offers several advantages over a basic soldering iron. It provides precise temperature control, ensuring consistent soldering results across various projects. Here are some reasons why you may need a soldering station:

Precise Temperature Control: Soldering stations provide precise temperature control, allowing you to set and maintain the desired temperature for your soldering tasks. This is especially important when working with delicate components or specific soldering requirements, as different materials and solder types require different temperatures. The ability to control the temperature ensures consistent and reliable soldering results.

Stability and Accuracy: Soldering stations offer stability in maintaining a constant temperature throughout your soldering process. This stability helps prevent temperature fluctuations that can lead to inconsistent solder joints or damage to sensitive components. With accurate temperature control, you can achieve precise soldering and create reliable connections.

Safety Features: Many soldering stations come equipped with safety features to protect both you and your work. These features may include temperature stability indicators, overheat protection, and auto-shutoff functions. They help prevent overheating, reduce the risk of accidents, and ensure safe operation, making soldering stations suitable for users of all skill levels.

Ergonomic Design: Soldering stations often feature ergonomic designs with comfortable handles and heat-resistant materials. These design elements enhance user comfort during prolonged soldering sessions, reducing fatigue and improving overall efficiency. An ergonomic soldering station allows for better control and maneuverability, resulting in more precise and accurate soldering.

Versatility: Soldering stations are versatile tools that can handle a wide range of soldering applications. They can accommodate different soldering tips, allowing you to choose the right tip size and shape for your specific project. Whether you're working on electronics, jewelry, or other soldering tasks, a soldering station provides the flexibility to meet your diverse needs.

Long-Term Cost Savings: While soldering stations may have a higher initial cost compared to basic soldering irons, they often offer better durability and longevity. Quality soldering stations are designed to withstand continuous use, and their replaceable soldering tips allow for easy maintenance and prolong the lifespan of the tool. By investing in a soldering station, you can save money in the long run by avoiding frequent replacements of inexpensive soldering irons.

In the next we will share how does a soldering station work and what’s the difference between a soldering station and a soldering iron. View more soldering stations on AiXun official website!

WhatsApp

WhatsApp