In the world of electronics repair and manufacturing, micro soldering stands as a specialized skill that requires a steady hand, exceptional precision, and an eye for detail. As electronic devices continue to shrink in size, the demand for micro soldering has grown exponentially. This article explores the challenges faced by professionals engaged in micro soldering and the techniques they employ to overcome them.

Miniaturized Components

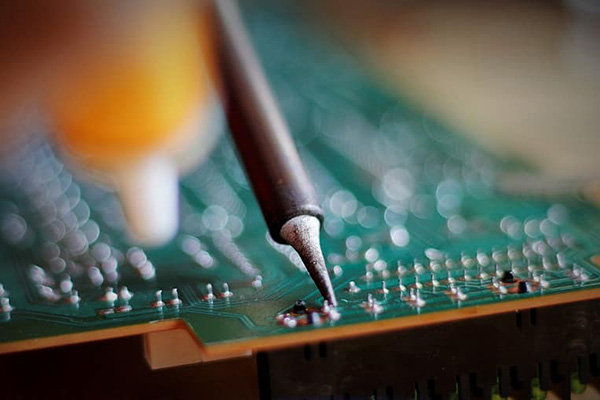

Micro soldering involves working with components that are often barely visible to the naked eye. The miniature size of these components, such as resistors, capacitors, and microchips, presents a significant challenge for soldering. The process requires soldering joints that are delicate and accurate, with minimal room for error.

Heat Management

The precise application of heat is crucial in micro soldering. Excessive heat can damage the delicate components or adjacent parts, leading to irreparable damage. Moreover, overheating can cause solder joints to melt or bridge, resulting in shorts or faulty connections. Micro soldering experts must carefully manage the heat and employ techniques such as hot air pencils or specialized soldering irons with adjustable temperature controls.

Stability and Accessibility

Micro soldering demands exceptional stability and accessibility. Working with tiny components requires a steady hand and a controlled environment. Even a slight hand tremor or an unsteady workspace can lead to disastrous consequences. Additionally, accessing the soldering points in cramped spaces or intricate circuitry can be a time-consuming and demanding task. Patience and meticulousness are essential traits for micro soldering professionals.

Soldering Techniques

Various soldering techniques are employed to meet the challenges of micro soldering. These techniques include drag soldering, where the soldering iron is dragged along the component's pins, and reflow soldering, which utilizes heat to melt pre-applied solder paste. Additionally, experts may use microscopes or magnifying lenses to enhance visibility and ensure precise soldering.

Component Sensitivity

Many electronic components, particularly those found in microelectronics, are sensitive to heat and electrostatic discharge (ESD). The slightest heat or static electricity can cause damage, rendering the component unusable. Professionals engaged in micro soldering must take appropriate precautions to prevent ESD, such as grounding themselves and using ESD-safe tools and workstations. They may also utilize specialized fluxes and soldering materials to minimize the risk of damage.

Conclusion

Micro soldering is a demanding and highly specialized skill that requires expertise, patience, and attention to detail. As the electronics industry continues to produce smaller and more intricate devices, the challenges faced by micro soldering professionals will persist. However, through careful technique selection, heat management, and the utilization of advanced tools, these challenges can be overcome. The work of micro soldering professionals plays a crucial role in ensuring the functionality and repairability of modern electronic devices. Check out micro soldering kit on AiXun website.

WhatsApp

WhatsApp