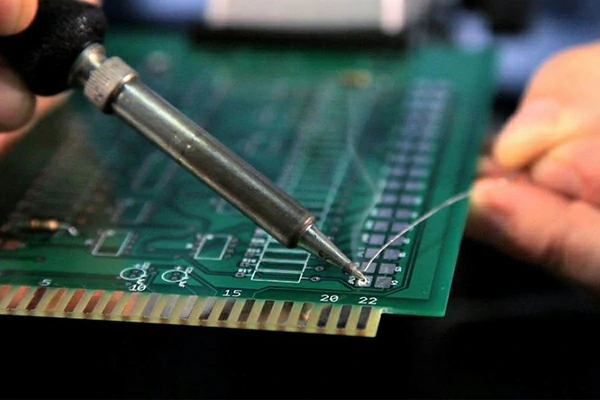

During the soldering process, the soldering tip comes into contact with various substances and, over time, collects residues that need to be cleaned. To keep the tip in good condition, it is essential to follow basic soldering procedures and to prevent oxidation of the pre-tinned area.

In lead-free soldering, due to the high tin content of lead-free solder, combined with the high temperature operation of the soldering iron tip and the diffusion of tin, the wear and voids in the soldering iron tip are more pronounced and the life of the soldering iron tip is significantly reduced. The following suggestions are made for the use of soldering iron tips:

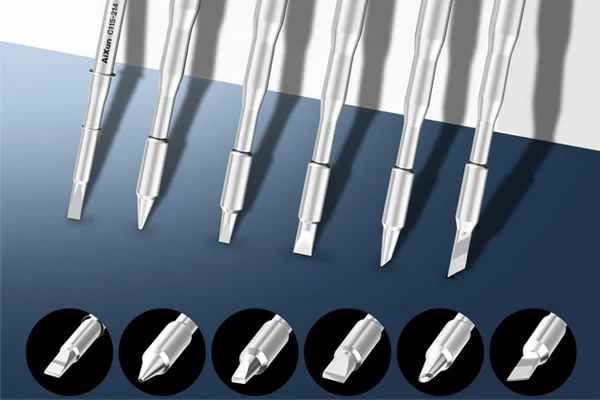

1. A soldering tip with the largest contact area with the soldering joint can produce the most effective heat transfer, allowing the operator to quickly solder high quality joints.

2. You should choose a soldering tip that has a good path to transfer heat to the soldering joint. A shorter tip can provide more precise control. You may need to use a longer or angled tip when soldering precision assembled PCBs..

Selection of soldering temperature---Too high temperature will weaken the function of the soldering tip, so choose the lowest possible temperature. At this time, the temperature recovery force of the soldering tip is excellent, and the lower temperature can fully solder, which can protect the temperature-sensitive components.

Cleaning the soldering tip---The soldering tip should be cleaned regularly. After soldering, the oxides and carbides from the residual flux on the soldering iron tip will damage the soldering iron tip, causing soldering defects or reducing the thermal conductivity of the soldering iron tip. If the iron is used continuously for a long time, the oxide on the tip should be removed once a week to prevent damage to the tip and to reduce the temperature.

When not in use --- When not in use, do not leave the soldering iron tip at high temperature for a long time, as this will cause the flux on the soldering iron tip to turn into oxides, which will reduce the thermal conductivity of the soldering iron tip.

After use -- After use, the soldering iron tip should be wiped clean and plated with a new layer of tin to prevent oxidation of the soldering iron tip.

A. Check and clean the soldering iron tip

!Note: Never use a file to remove oxides from the tip of the soldering iron.

1. The set temperature is 250℃.

2. After the temperature stabilizes, clean the tip of the soldering iron with a metal wire or cleaning sponge and check the condition of the soldering station.

3. If the tinned part of the soldering iron tip contains black oxide, a new layer of tin can be plated, and then the soldering iron tip can be wiped clean with a metal wire or cleaning sponge. Repeat the cleaning until the oxide is completely removed and then apply a new layer of tin.

4. If the tip is deformed or badly corroded, replace it with a new one.

B. Why can’t a “non-tinned” soldering iron tip be used?

A "non-tinned" tip is one that cannot be wetted with solder. The exposed plating will oxidized and the heat transfer from the tip will be ineffective.

The "not tinned" soldering iron tip is caused by the following reasons:

- Failure to cover the tip with fresh solder when not in use

- The soldering iron tip is at high temperature

- Insufficient melting during soldering work

- Wipe the tip on a dry or dirty sponge or cloth. Cleaning should be done with a clean, moist, industrial grade sulfur-free sponge or wire

- The solder is highly corrosive or the iron plating is impure, or the soldering surface is not clean.

C. Recovering a soldering tip that is not tinned

- Remove the tip from the soldering pen after it has cooled.

- Use antioxidant or special tip cleaning wire to remove dirt and oxides from the tinned surface of the tip.

- Insert the soldering iron tip into the handle and wrap the newly exposed tinned surface of the soldering iron tip with rosin-containing tin wire (φ0.8 or higher), then turn on the power switch of the soldering station.

D. Prolonging the life of the soldering tip

- Moisten the tip with fresh solder after each use. This will prevent oxidation of the tip and extend its life.

- Try to use a lower temperature if possible. A lower temperature can reduce oxidation of the tip and make it easier to solder components.

- Use thin tips only when necessary. The coating on thin tips is not as durable as the coating on thick and blunt tips.

- Do not use the tip as a probe. Bending will cause the coating to crack and shorten the life of the tip.

- Use less active rosin flux, as the high active rosin content will accelerate the corrosion of the soldering iron tip coating.

- Try to turn off the power when not in use to prolong the life of the tool.

- Do not apply too much pressure to the soldering iron tip. More pressure does not mean faster heat transfer. To improve heat transfer, the solder must be melted to form a soldering bridge for heat transfer between the soldering iron tip and the soldering joint.

Visit each category to discover several other products offered by AiXun for soldering, rework work. The brand guarantees valuable products with repair services and enhanced production.

WhatsApp

WhatsApp