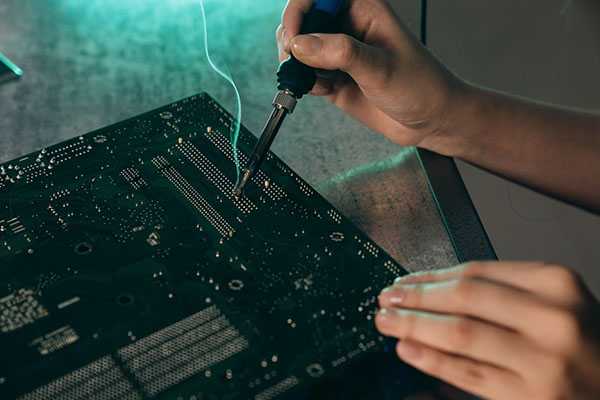

Surface Mounted Device (SMD) soldering is a process used to assemble electronic components onto a printed circuit board (PCB). This process is used to create complex, high-precision electronic assemblies. SMD soldering requires specialized tools and equipment, such as SMD soldering stations.

SMD soldering stations are designed to provide a safe and efficient way to solder SMD components onto a PCB. These soldering stations are used in a wide range of industries, from consumer electronics to aerospace and defense. In this article, we’ll discuss the basics of SMD soldering stations and how they can be used to create high-quality electronic assemblies.

An SMD soldering station is a specialized tool used to solder SMD components onto a PCB. The station consists of a soldering iron, a soldering tip, and a soldering station. The soldering iron is used to heat up the component and the soldering tip is used to apply the solder. The soldering station is used to control the temperature of the soldering iron and the soldering tip.

The soldering station is usually connected to a power source and is equipped with a temperature control system. This system allows the user to adjust the temperature of the soldering iron and the soldering tip. The temperature control system also allows the user to set a pre-determined temperature for the soldering process.

The soldering station also includes a soldering stand, which is used to hold the soldering iron and the soldering tip. The soldering stand is usually made of metal or plastic and is designed to keep the soldering iron and the soldering tip in place while the user is soldering.

There are several benefits to using an SMD soldering station. The most important benefit is the ability to precisely control the temperature of the soldering iron and the soldering tip. This allows the user to solder SMD components with greater accuracy and reliability.

Another benefit of using an SMD soldering station is the ability to quickly and easily change the soldering tip. This allows the user to quickly switch between different types of soldering tips, depending on the type of component being soldered.

Finally, using an SMD soldering station also helps to reduce the risk of damaging the PCB or the components. This is because the soldering station is designed to provide a safe and controlled environment for the soldering process.

There are several different types of SMD soldering stations available on the market. The most common type is the benchtop soldering station. This type of station is designed to be used on a workbench or table. It typically includes a soldering iron, a soldering tip, a soldering stand, and a temperature control system.

Other types of soldering stations include hand-held soldering stations and hot-air soldering stations. Hand-held soldering stations are designed to be used in tight spaces and are typically used for rework or repair jobs. Hot-air soldering stations are used to solder SMD components with a hot air gun.

SMD soldering stations are an essential tool for creating high-quality electronic assemblies. These stations provide a safe and efficient way to solder SMD components onto a PCB. They also allow the user to precisely control the temperature of the soldering iron and the soldering tip. Finally, they help to reduce the risk of damaging the PCB or the components. Find the best SMD soldering stations please feel free to contact AiXun.

WhatsApp

WhatsApp