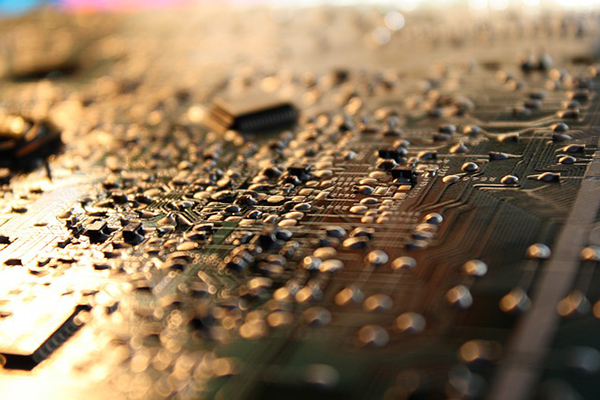

BGA, full name is "ball grid array". It is to blow the solder balls on the CPU contacts with a heat gun through the ball planting board, and then align them with the main board PCB for heating and soldering. At present, this technology is widely used in notebooks and all-in-one motherboards with embedded CPU. What are the ways of BGA ball planting?

Let's learn about it with AiXun precision soldering experts.

Place the BGA components printed with flux or solder paste on the workbench, with the side of the flux or solder paste facing up. Prepare a template that matches the BGA pad in advance. The opening size of the template should be 0.05-0.1mm larger than the diameter of the solder ball. Use pads around the template to place it on top of the BGA components that have printed flux or solder paste. Make the distance between the template and the BGA equal to or slightly lower than the diameter of the solder balls, and align under the microscope. Sprinkle the solder balls evenly on the template, and take off the unnecessary solder balls with pliers, so that there is exactly one solder ball in each leak hole on the surface of the template. Remove templates, check and fill in.

The ball-planting method of brushing an appropriate amount of solder paste needs to increase the thickness of the template when processing the template, and slightly enlarge the opening size of the template, print the solder paste directly on the BGA pad. Solder balls are formed after reflow due to surface tension. Therefore, it is necessary to ensure that the solder paste is applied just appropriate when planting balls on the BGA rework station, otherwise the ball planting will fail. AiXun offer lead free solder paste flux.

Select a BGA ball planting mold corresponding to the BGA pad. The mold opening size should be 0.05-0.1mm larger than the diameter of the solder ball. Spread the solder balls evenly on the template, and shake the ball planter to ensure that there is a tin in the mold leak hole. ball. Then suck the BGA device with the flux printed on the suction nozzle, and stick the solder ball to the corresponding pad of the BGA device with the help of the viscosity of the flux or solder paste. Clamp the outer frame of the BGA device with pliers, turn off the vacuum pump, place the solder balls of the BGA device on the workbench, check whether there are missing solder balls, and fill them up with pliers if any.

The manual mounting ball planting method is to manually place the BGA device printed with flux or solder paste on the workbench, with the flux or solder paste side upward. Use pliers to place the solder balls one by one just like a patch. This method is only suitable for individual and or some small companies. This method has high requirements for rework operator and takes long time for working, and the yield rate of ball planting rework is low.

ShenZhen AiXun Intelligent Hardware Co., Ltd. was established in 2018. It is a high-tech enterprise in precision electronic soldering. The company's business mainly involves intelligent software and hardware development, material analysis, mobile phone repair, precision circuit board soldering, repair and so on. If you have any questions of business inquiry, feel free to contact AiXun.

WhatsApp

WhatsApp