Soldering iron tips are important for soldering. The material they are made of affects the quality of the job. The best material for soldering iron tips is typically copper or copper alloys.

Copper is a highly conductive metal, making it ideal for transferring heat quickly and efficiently during soldering. Copper also has a high melting point, which helps to prevent the tip from melting during the soldering process. Copper alloys like brass, bronze, and nickel-silver are good for soldering iron tips. They have copper's conductivity and the durability of other metals.

When selecting a material for a soldering iron tip, one must consider the type of soldering job being performed. If the job needs precise soldering, brass may be better than copper because it is softer. Additionally, if the soldering job involves working with delicate components, then a softer metal may be more suitable.

Choose the right material for the soldering iron tip and keep it in good condition. This means regularly cleaning the tip with a damp cloth or brush and using the correct soldering flux. Furthermore, it is important to regularly inspect the tip for signs of wear and tear, and to replace it when necessary.

Learn more>>> How to Clean, Tin, and Maintain Soldering Iron

Choose the correct material for the soldering iron tip and maintain it well to guarantee a good soldering result consistently.

The best material for a soldering iron tip depends on the specific application and personal preference. The best material for soldering iron tips is usually copper with a coating of iron, nickel, or both. Here are the reasons why:

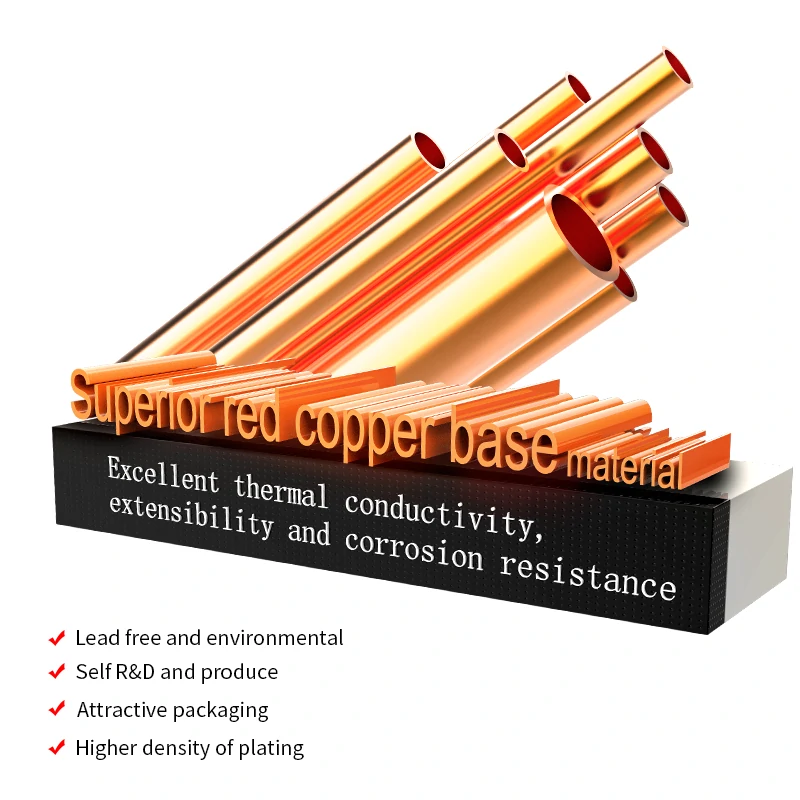

Copper Core: Copper has excellent heat conductivity, allowing for rapid and efficient heat transfer from the soldering iron to the tip. This ensures quick heat-up and temperature recovery during soldering tasks.

Iron Plating: Iron plating provides durability and corrosion resistance to the tip. It also helps improve heat transfer from the core to the solder joint, allowing for better soldering performance.

Nickel Plating: Nickel plating adds an extra layer of protection against corrosion and oxidation. It also improves the wetting characteristics of the solder, making it easier to form reliable and strong connections.

The combination of a copper core with iron or nickel plating strikes a balance between heat conductivity, durability, and corrosion resistance. These tips provide good thermal transfer, longevity, and compatibility with various solder alloys.

It's worth noting that for specialized applications or specific soldering tasks, different tip materials may be recommended. Special coatings like titanium, silver, or gold can be used on tips for soldering delicate parts or high-frequency tasks. However, these specialty tips are typically more expensive and may not be necessary for general soldering purposes.

A soldering iron tip with a copper core and iron or nickel plating is ideal for most soldering tasks. It is highly efficient in transferring heat, has a long lifespan, and is resistant to corrosion.

WhatsApp

WhatsApp