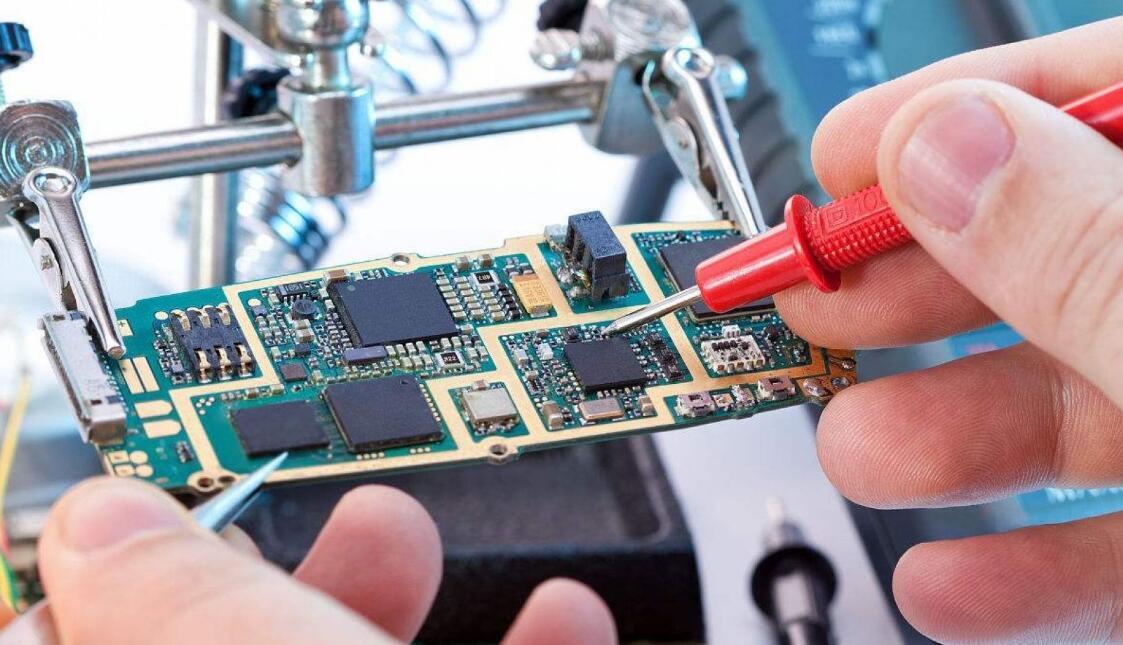

Precision soldering refers to the soldering process that can achieve the purpose of precise forming and manufacturing. Generally, methods with high energy density soldering can achieve the purpose of precision soldering.

Which soldering iron tip is suitable for precision electronic soldering?

Tapered tip is best for precision work

Most tapered tips have a pointed shape and are mainly used for precision soldering. Tapered tip concentrates heat to a small area, making it suitable for most surface mount components and other small tasks.

What temperature should I solder at?

600°- 650°F (316°- 343°C) is a good starting point for lead-based solder and 650°- 700°F (343°- 371°C) is a good starting point for lead-free solder. Hold the tip against the leads and contacts/pads for a few seconds. The idea is to bring both to soldering temperature at the same time.

How to do precision soldering?

Make sure your soldering iron is fully heated and touch the tip to the end of one of the wires. Put it on the wire for 3-4 seconds. Hold the iron in place and touch the solder to the wires until fully covered. Repeat the process on the other wire.

Matters needing attention when precision soldering:

1. When the power is turned on, the temperature of the soldering iron tip is in a high temperature state. Since abuse may cause burns or fires, please strictly observe the following items: Please avoid the abuse of this soldering station, and use this product according to the operating instructions.

2. Do not touch the metal parts near the tip of the soldering iron.

3. Never use the soldering iron tip near flammable objects.

4. Inform other personnel that the soldering iron tip is easily burnt and may cause dangerous accidents. Power should be turned off during breaks or after work.

5. Do not touch the tip of the soldering iron directly to prevent burns.

6. Do not strike the soldering iron on the workbench to remove the flux residue, this may seriously damage the soldering iron.

7. Never use a soldering iron tip for work other than soldering.

WhatsApp

WhatsApp