With the high speed development of machining technology, the use of electric soldering irons is constantly rising to the new level. However, soldering has strict requirements for temperature control. If these requirements cannot be meet, it would easy to cause equipment damage.

For the use of soldering iron tip , the ideal situation is that the electric soldering iron can achieve temperature stability, and the working temperature is not disturbed by various external conditions. During the soldering process, change the length of working time to complete soldering of different soldering component.

This is determined by the actual application needs of the soldering iron. Generally speaking, the temperature when the soldering iron can solder a tin point in 4 seconds is a more suitable temperature. If the soldering iron turns purple, it means that the temperature is too high

Specifically, for the DIP electronic material, the temperature of the soldering iron tip should be set between 330-370 °C. For the STM material, the temperature should be between 300-320 °C. The maintenance of the buzzer requires a temperature of 270-290 °C. The soldering temperature of the large component feet cannot exceed 380 °C. In addition, for special materials, it is necessary to make a special setting for the temperature.

1. 20-25W, the corresponding temperature is 200-250 °C;

2. 30-35W, the corresponding temperature is 250-300 °C;

3. 40-45W, the corresponding temperature is 280-350 °C;

4. 50W, the corresponding temperature is 320-380 °C;

5. 60W, the corresponding temperature is 320-400 °C;

6. 75-80W, the corresponding temperature is 350-400 °C;

7. 100W, the corresponding temperature is 380-450 °C;

Different wattages have different heating temperatures.

For the solder joints of SMD components and thin-foot components (such as wires, LED, etc.), the temperature of the soldering iron is generally implemented according to the following standards:

Lead soldering: the temperature is controlled at 250-350 °C;

Lead-free soldering: the temperature is controlled at 320-400 °C;

For solder joints with faster heat dissipation and more tin addition (such as battery positive and negative polarity sheets, etc.), the temperature of the soldering iron is generally implemented according to the following standards:

Lead soldering: the temperature is controlled at 280-380 °C;

Lead-free soldering: the temperature is controlled at 350-420 °C.

In the trend of the electronic manufacturing industry, soldering iron soldering is basically inseparable, whether it is manual soldering or automatic soldering.

Refer to Manufacturer's Guidelines:

Always check the solder manufacturer's recommendations for the ideal temperature range for their product. The solder package or datasheet usually provides the appropriate temperature range to achieve the best results with their specific solder.

Preheating and Thermal Management:

Preheating the workpiece or using a heat sink on sensitive components can help to manage the temperature during soldering. Preheating reduces the temperature drop during the soldering process and ensures better flow of solder.

Experiment and Practice:

Soldering is an art that improves with practice. If you are unsure about the right temperature, start with a lower temperature and gradually increase until you achieve the desired results. Practice on scrap materials before working on critical projects.

Temperature Control:

Invest in a soldering iron with adjustable temperature settings and good temperature control capabilities. A variable-temperature soldering station allows you to fine-tune the temperature according to your needs.

No matter what kind of equipment, the soldering temperature is particularly important in the soldering process. Therefore, before starting work every day, QA person are required to bring a thermometer to measure the temperature of the soldering iron to ensure that the actual temperature of the soldering iron is consistent with the displayed temperature. If the deviation is exceeded, the temperature calibration must be continued; excessive temperature will cause cracks, Phenomena such as blackening of solder joints, if the temperature is too low, there will be cold soldering, empty soldering and other phenomena, which are common poor soldering caused by temperature .

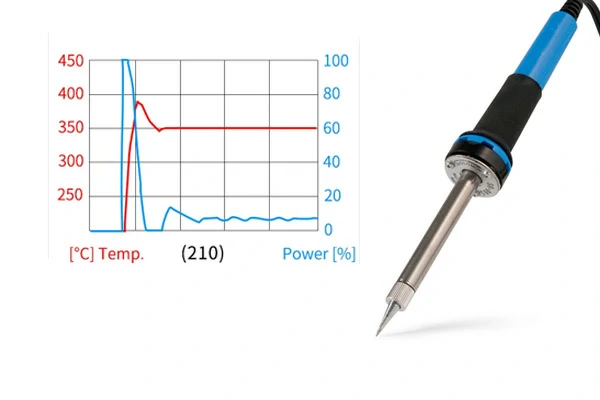

Temperature management of the soldering iron tip is very important. Based on the above situation, AiXun R&D the DT01 OLED intelligent digital display tester

This DT01 smart thermometer for Soldering Iron Tip with digital display is a temperature tester for all items that need temperature measurement, such as soldering iron and soldering tips, hot air gun, surface, liquid and so on. The temperature test range of this device is from 0-500°C. The large OLED HD display makes the temperature clear and visible. It’s equipped with 10pcs temp sensors and 1pc thermocouple with K-type socket, meeting different temperature measurement requirements. The temp change curve design helps to show the temp curve recording and playback accurately and clearly. By connecting with type-C or bluetooth, it can also calibrate temp by matching with T420D soldering station.

Matched with AiXun smart soldering tools, brings you simple and efficient work!

WhatsApp

WhatsApp