When soldering, when flux is applied to the electrical leads to be soldered, it helps to remove oxidation and prevents airflow to the leads, preventing further oxidation. Solder adheres more easily to unoxidized metal, which will cause the solder to flow evenly over the electrical leads. Since the solder is evenly present in the electrical leads, its conductivity is also improved.

Rosin flux

One of the most used fluxes for soldering, is refined mainly from natural resins extracted from the oleoresin of pine trees. Modern rosin is mixed with different fluxes to optimize its performance.It is only effective when heated and melted, and is usually safe for components on unheated boards. Rosin flux can be cleaned with an isopropyl alcohol solution.

Organic acid flux

Which is also commonly used for soldering circuits. This flux removes oxidation from the wires faster. Removing this flux from the circuit is important because the cause of a short circuit is the residue left behind when soldering.Organic acid fluxes are water-soluble and can be cleaned with water.

Inorganic flux

Inorganic flux is used for higher strength metals such as copper and stainless steel. It is not commonly used for electrical circuits, but mainly for plumbing applications.

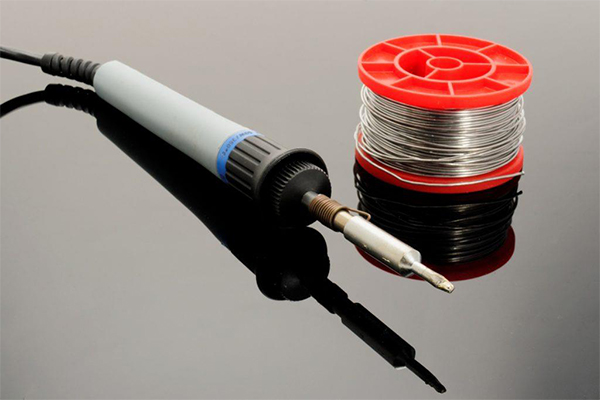

There is flux-available solder inside the solder wire, called flux-cored solder. Flux cored solder has flux in the center of the solder wire. Most applications do not require additional flux, but using additional flux can still make the solder easier to use for some project work. When choosing a flux-cored solder, it is important to use rosin-cored solder in electrical applications. Acid core solder should only be used for plumbing applications.

I recommend using aixun solder wire. The flux is evenly present in the solder wire and can be better utilized during soldering.

WhatsApp

WhatsApp