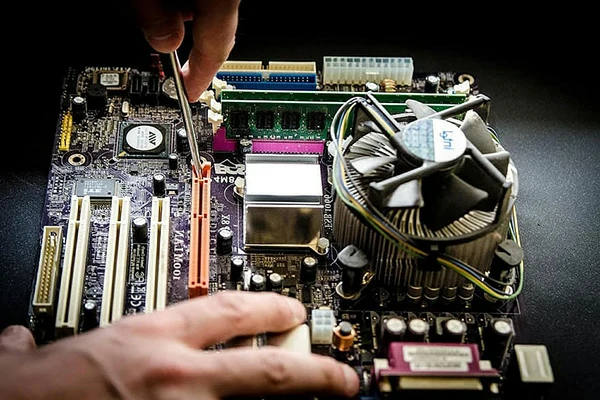

Anyone who works with electronics must possess the skill of soldering. It is a process used to join two metals together using a special alloy or metal filler known as solder. Soldering is used in a variety of applications, from creating electrical circuits to repairing jewelry. However, soldering can be a tricky process, particularly when it comes to working with surface-mount devices (SMDs). This is where SMD soldering station come in.

SMD soldering stations are specialized tools designed to make soldering SMD easier and more accurate. They are equipped with a soldering iron, a microscope, and a variety of other tools to help you get the job done right.

Let’s take a look at what makes SMD soldering stations so great and why you should consider investing in one.

As you can see, SMD soldering stations are an invaluable tool for anyone who works with electronics. They are incredibly precise, portable, and versatile, making them a great investment for any professional or hobbyist. So if you’re looking for a way to make soldering SMDs easier and more accurate, then an SMD soldering station is the perfect choice.

Now that you know the wonders of SMD soldering stations, it’s time to start shopping for one. With so many options on the market, it can be difficult to know which soldering station is right for you. Here are some tips to help you choose the right SMD soldering station for your needs.

1. Consider the type of work you’ll be doing. Different soldering stations are designed for different types of work. If you’re mainly doing hobby projects, then a basic soldering station may be enough. However, if you’re a professional, you may need a more advanced station with additional features.

2. Consider the size of your workspace. If you have a limited amount of space, then you’ll want to choose a soldering station that is compact and easy to store. On the other hand, if you have plenty of space, then you may be able to go for a larger station with more features.

3. Look for features that are important to you. Different soldering stations have different features, so it’s important to consider what features are most important to you. Do you need adjustable temperature settings? Do you need a soldering iron with a long cord? Do you need a station with a built-in vacuum system?

4. Consider the cost. The cost of soldering stations can vary greatly, ranging from a few hundred dollars up to several thousand. It’s important to consider your budget when choosing a station.

5. Read reviews. Reading reviews from other users can be a great way to get an idea of how well a soldering station works. Look for reviews from people who have used the same type of station that you’re considering.

A SMD (surface mount device) soldering station is a powerful tool that can be used to solder components to a circuit board quickly and accurately. However, it is important to properly maintain your SMD soldering station to ensure it is working properly and safely. Here are some tips on how to maintain your SMD soldering station.

1. Clean the Soldering Iron Tip Regularly

The soldering iron tip is the most important part of your SMD soldering station as it is the part that actually comes into contact with the components. It is important to clean the tip regularly to ensure it is free of any residue or debris. You can clean the tip with a damp sponge or a brass wire brush.

2. Check the Tip Temperature

The temperature of the tip should be adjusted to the recommended setting for the components you are soldering. Too high a temperature can damage the components and too low a temperature can cause poor soldering. You can use a digital thermometer to check the temperature of the tip.

3. Use the Right Solder

Using the wrong type of solder can cause poor soldering and can even damage the components. Make sure to use the correct types of solder for the components you are working with.

4. Check the Solder Flow

The solder should flow smoothly and evenly. If the solder is not flowing properly, the components may not be soldered correctly. Make sure to check the solder flow regularly and adjust the temperature and/or the amount of solder as needed.

5. Store the Soldering Station Properly

When not in use, make sure to store your SMD soldering station in a dry, dust free environment. This will help to ensure that the components and the soldering iron tip are not damaged by moisture or dust.

By following these tips, you can ensure that your SMD soldering station is working properly and safely. Taking the time to properly maintain your soldering station will help to ensure that you get the best results when soldering components to a circuit board.

With the right station, you’ll be able to make precise and secure connections with SMD in no time. Once you’ve found the perfect SMD soldering station, it’s time to get to work. So don’t wait any longer – start discovering the wonders of SMD soldering stations today!

WhatsApp

WhatsApp